High Power Connectors

High Voltage Connectors

High Power Interconnect Solutions

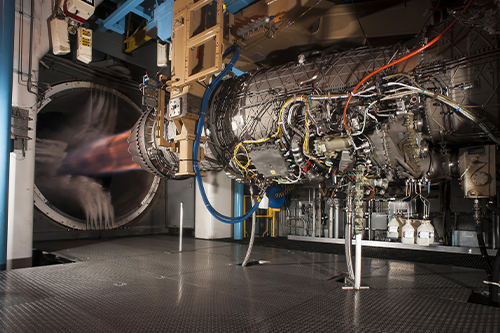

Amphenol Aerospace has led the connector industry with military and aerospace power distribution connector solutions for decades. Whether it’s helping to power military ground vehicles, military and commercial aircraft systems, or the latest space launch vehicles, Amphenol Aerospace has been at the forefront of connector innovation and development. As we move beyond the current mil-spec standards to more custom, high-power needs, our connector designs and solutions have continued to evolve as the demand for more power increases.

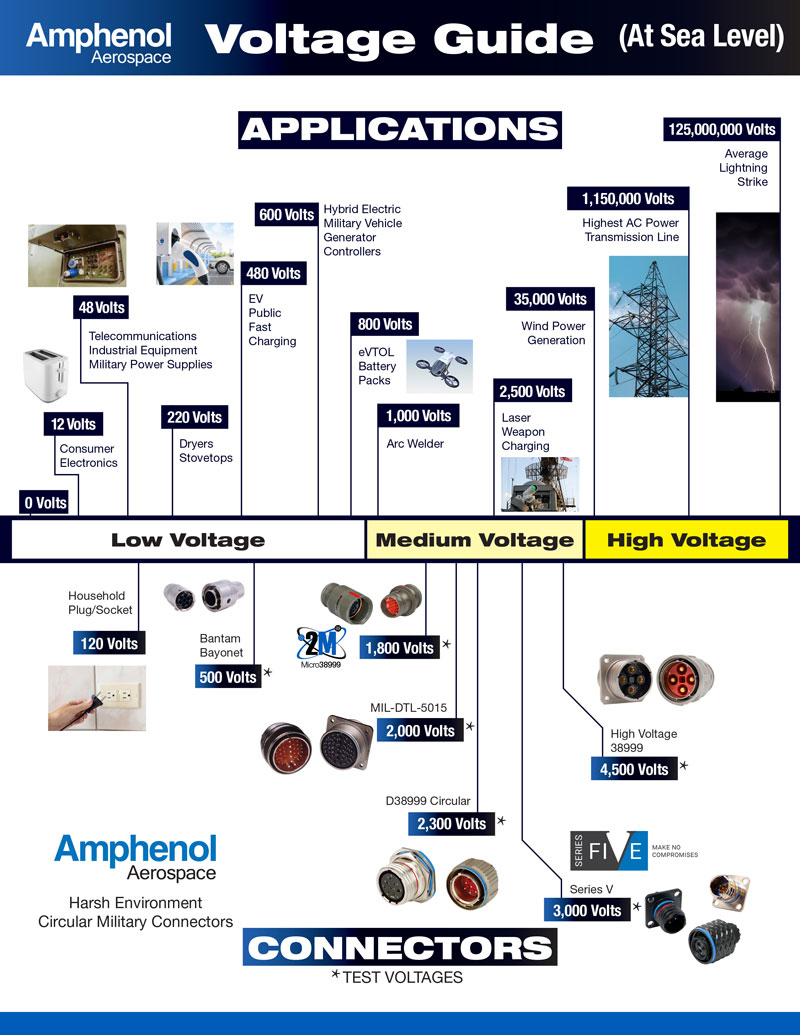

High Voltage and Current Requirements Are Not Going Away

In fact, they’re only going to continue growing.

As mission requirements become more diverse and demanding, military and aerospace systems are being designed to handle a wider range of tasks. This versatility often results in the integration of additional subsystems and technologies, driving up the complexity and power consumption of systems.

Advancements in sensor technologies, data processing needs, electronic warfare integration, communication demands, propulsion electrification, energy efficiency considerations, challenges in miniaturization, and the pursuit of expanded mission capabilities are all factors driving up power consumption. Higher voltages are being employed at greater scale to transmit power over longer distances with minimal loss, with increased current necessary for delivering more power to various components.

Connectors that can facilitate power distribution requirements beyond what standard circular power connectors are capable of are essential in new military and aerospace development, especially with the push toward electrification and hybrid-electric platforms.

High Volts, High Amps

As electrification technologies continue advancing, high voltage and amp considerations need to be considered. The evolving landscape of hybrid-electric and fully electric applications in commercial and military industries requires tailored voltage and amp specifications for optimal performance.

Next-generation electrification applications require interconnect systems with material and design enhancements that allow them to safely accommodate high voltage and high-amp power systems operating at a variety of temperatures and altitudes. Striking this balance is essential for the integration and scalability of future electrification technologies.

Ruggedized Power Connectors for Any Application

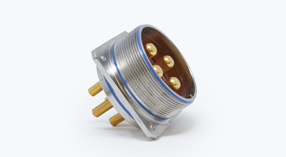

Amphenol Aerospace’s versatile high-power connector series offers a wide selection of options. They feature our proven Matrix 5015 and GT-5015 interfaces with a variety of tooled insert arrangements to ensure capability with any ruggedized high-power application.

High Power Key Features |

|

|---|---|

| Enhanced Performance: | Achieve 40-50% increased current carrying capability compared to standard 5015 connectors. |

| Versatile Coupling: | Choose between threaded or bayonet coupling options to suit your specific needs. |

| Swift Customization: | Expedite design-in time with catalog customization options. |

| Compatibility: | Seamlessly integrate with existing cabling designs using standard interfaces in scenarios requiring high performance. |

| Reliability in Harsh Environments: | Ensure superior performance in demanding conditions with gold-plated contacts. |

Customer Options |

|

|---|---|

| Contact Termination Methods: | Select from crimp, male and female threaded termination, solder, PCB, and bus-bar options. |

| Environmental Resilience: | Choose epoxy backfilled options to enhance environmental performance. |

| Advanced Socket Contacts: | Leverage low resistance RADSOK® technology and TEMPER-GRIP contacts for high current carrying capability at temperatures exceeding 200°C(392°F). |

| Versatile Configurations: | Choose from more than 25 tooled insert arrangements for a current carrying capacity ranging from 50 to nearly 1000 amps per connector. |

| Advanced Plating: | Explore standard and proprietary plating options, including RoHS/Reach-compliant Durmalon and Nickel Teflon plating capable of withstanding 500 hours of salt spray exposure. |

| Tailored Solutions: | Contact the factory for quick-turn custom designs addressing specific mechanical or electrical requirements. |

Other Key Features |

|

|---|---|

| Shock Resistant: |

|

| Operating Temperature Range: |

|

| Environmental Seal: |

|

| Durability: |

|

Applications

- Hybrid-Drive/Electric Vehicles

- Electric Vertical Takeoff and Landing (eVTOL) Aircraft

- Next-Generation Electric Commercial Aircraft

- Laser Power Systems

- Ruggedized Power Converters

- Power Distribution

- Fast Charging

- Battery Connections

- And More

See our Product Configurator for available drawings and 3D models.