Ruggedized Media Converters, Ethernet Switches, Active Contacts, and High Speed/High Density Connectors

Integrated Solutions Products combines our most advanced technologies with our long history of connector design and development in the Military and Aerospace markets to provide custom products that perfectly match future application needs in avionics, C4ISR, space systems, and embedded systems. Our portfolio is constantly expanding.

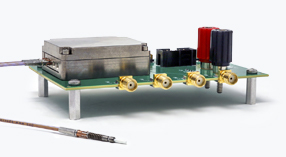

Media Converters

We have a wide range of Media Converters which are integrated connectors that convert to fiber optics or between protocols. Many use a common D38999 Series III interface. Our Agnostic Media Converters include copper-to-fiber media converters that work across a variety of protocols, either single-mode or multi-mode, at speeds up to 10 Gbps. Our Ethernet Media Converters include stand-alone, embedded, or 3U/6U VPX and work with many protocols -- 1GBase-T, 10GBase-T, Fiber XAUI, 10GBase-SR, and others. Video Media Converters handle both fiber and copper DVI and SDI conversion.

Ethernet Switches

Our rapidly expanding Ethernet Switches product line come in a number of form factors -- 3U and 6U VPX with up to 144 channels, 32-Channel Ethernet 10G Switches, and Rugged Standalone 120-Channel Ethernet Switchboxes. These can support speeds between 10G and 25 Gbps.

Active Fiber Optic and High Speed Contacts

Active Contacts -- both High Speed and Fiber Optic -- have recently been developed. The Active Fiber Optic Contacts are Quadraxial contacts that have embedded fiber optic transmitting and receiving; speeds up to 4.25 Gbps and 10.3125 Gbps. Active High Speed Contacts are Quadraxial contacts that embed boosting, conditioning, transforming, and other value-add functionality to support USB 3.0 and 1G Ethernet.

High Speed/High Density Connectors

The newest High Speed/High Density Connectors in the Integrated Solutions Product portfolio include the Centaur Series which combines our extensive legacy of Mil-Spec connectors with the latest in high-speed technology, providing both a durable and high-bandwidth system that supports data rates up to 56 Gbps in a lightweight, aluminum D38999 Series III shell; the Centaur PCB Series which is an extension of the Centaur Series, but has a compliant eye press-fit tail option and supports data rates up to 10 Gbps with options of 32 to 40 differential pairs to connect straight to a PC board; and the Leap-AHRD High Speed Optical Module which, at 300Gb/s, is faster, smaller, more cost and power-efficient than most conventional datacenter interconnects. It requires only one square inch of board space and 5.4W of power. It is capable of speeds up to 25Gbps and distances up to 100 meters.

Amphenol Ruggedization Design

Amphenol integrated electronic products are designed and manufactured to our Ruggedization guidelines listed below. These guidelines ensure years of reliable operation in harsh environment applications where extreme operating temperatures, shock, vibration, and corrosive atmospheres are regularly experienced. Unless otherwise noted, the parts conform to the below specifications

TEMPERATURE:

- Operating Temperature- Thermal Cycles between -40ºC and 85ºC while device is operating

- Temperature is measured at chassis housing or card edge

- Storage Temperature- Thermal Cycles between -55ºC and 125ºC

HUMIDITY:

- Operating Humidity- Humidity cycle between 0-100% non-condensing humidity while device operating

- Storage Humidity- Humidity cycle between 0-100% condensing humidity

SEALING:

- Sealing can be optionally provided at the MIL-DTL-38999 interface with up to 10-5 cc/sec performance

SHOCK AND VIBRATION:

- Sine Vibration - 10g Peak, 5-2,000Hz

- Based on a sine sweep duration of 10 minutes per axis in each of three mutually perpendicular axes. May be displacement limited from 5 to 44 Hz, depending on specific test.

- Random Vibration - 0.0005 @ 5Hz, 0.1 @ 15 Hz, 0.1 @ 2,000 Hz

- 60 minutes per axis, in each of three mutually perpendicular axes.

- 40 G Peak Shock Cycle

- Three hits in each axis, both directions, ½ sine and terminal-peak saw tooth, Total 36 hits.

FLUID SUSCEPTABILITIY:

- MIL-DTL-38999 receptacle interface per EIA-364-10E

ALTITUDE:

- -1,500 to 60,000 ft Altitude Testing w/ Rapid Depressurization

ELECTRONMAGNETIC COMPATIBILITY:

- Designed to comply with MIL-STD-461E

PRINTED CIRCUIT BOARD ASSEMBLIES:

- Conformal Coat

- Amphenol performs Conformal Coting to both sides of printed circuit board assemblies using HUSMISEAL IB31 in accordance with IPC-610, Class 3.

- Printed Circuit Board Rigidity

- Amphenol printed circuit boards are fabricated in accordance with IPC-6012, Class 3.

- Printed Circuit Board Fabrication

- Amphenol printed circuit boards acceptance criteria is in accordance with IPC-610, Class 3.

RELIABILITY PREDICTIONS (MTBF):

Amphenol can perform Mean Time Between Failure (MTBF) reliability analysis in full compliance with MIL-HDBK-217F-1 Parts Count Prediction and MIL- HDBK-217F-1 Parts Stress Analysis Prediction. We can also perform reliability analyses in full compliance of ANSI/VITA 51.1 if it is required or preferred over the later method