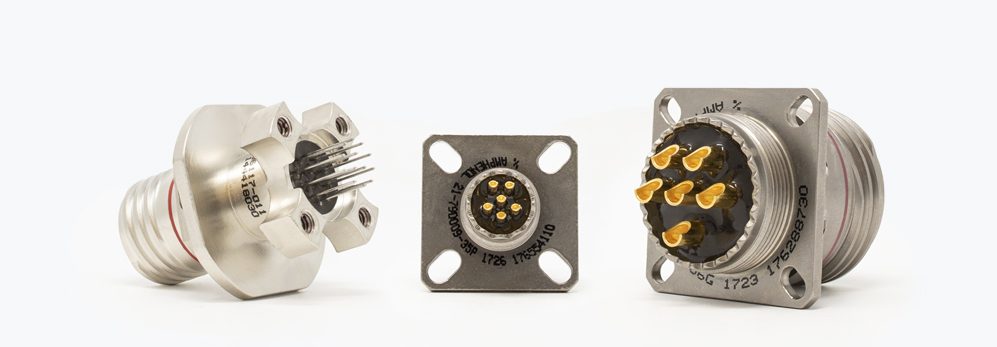

Epoxy Sealed Connectors

Contact:

Description:

Amphenol MIL-DTL-38999 Epoxy Sealed Hermetic Connectors offer superior electrical performance and a superior leak rate performance provided by an epoxy seal, coupled with the rugged design of a glass to metal seal connector.

Epoxy Sealed Hermetic Connectors are a lightweight alternative to glass sealed hermetic connectors and are available in custom configurations, including board mounting stand-offs and thru-bulkhead designs. These connectors utilize the same epoxy applied on Amphenol’s EMI Filter connectors.

Features & Benefits:

Hermetic Features:

- Leak rate of 1X10-7 cc He/sec or less

- Fused glass insert in a stainless steel shell

- Operating Frequency: 0-500 MHz

- Insulation Resistance: 1000 ohms at 25°C

- Dielectric Withstanding Voltage: Center to outer 500 VAC RMS at sea level

- Contact Resistance: Center and outer at 1 amp, 55 millivolts max. voltage drop at 25°C

Epoxy-Sealed Features:

- Leak rate less than 1x10-5 cc He/sec

- Maintained after 5 thermal shocks between -55C to +125C

Custom Features include but are not limited to:

- Special flanges

- PC Board mounting stand-offs

- PC Board mounding tails

- EMI filtering

- Bulkhead feedthrough configurations

- Crimp Termination

- Unique shell styles

- Exotic Material Options

- High pressure requirements

- High temperature requirements

SERVICE RATING*

| Service Rating | Suggested Operating Voltage (Sea Level) |

Test Voltage | ||||

| AC (RMS) | DC | Sea Level | 50,000 ft. | 70,000 ft. | 110,000 ft. | |

| M | 400 | 500 | 1300 VRMS | 550 VRMS | 350 VRMS | 200 VRMS |

| N | 300 | 450 | 1000 VRMS | 400 VRMS | 260 VRMS | 200 VRMS |

| I | 600 | 850 | 1800 VRMS | 600 VRMS | 400 VRMS | 200 VRMS |

| II | 900 | 1250 | 2300 VRMS | 800 VRMS | 500 VRMS | 200 VRMS |

** Please note that the establishment of electrical safety factors is left entirely in the designer’s hands since they are in the best position to know

what peak voltage, switching surges, transients, etc. can be expected in a particular circuit.

| Hermetic Shell Components | ||

| Material/Finish | Service Class | |

| Military | Commercial | |

| Stainless Steel | Y | Y |

| Stainless Steel with Nickel Plate | N | YN |

| Hermetic Connectors | ||||

| Finish | Suffix | Indicated Finish Standard for JT Types Listed Below | Indicated Finish Standard for LJT Types Listed Below | |

| Military | Commercial | |||

| Carbon Steel Shell Tin Plated Shell and Contacts |

JT( )H / JT( )Y JTL( )H / JTL( )Y |

LJT( )Y LJT( )H |

||

| Carbon Steel Shell Tin Plated Shell and Gold Plated Contacts | MS (D) | |||

| Stainless Steel Shell Gold Plated Contacts | MS (E) | (162) | JTS( )Y JTLS( )Y |

LJTS( )Y |