LMD and LMS

Contact:

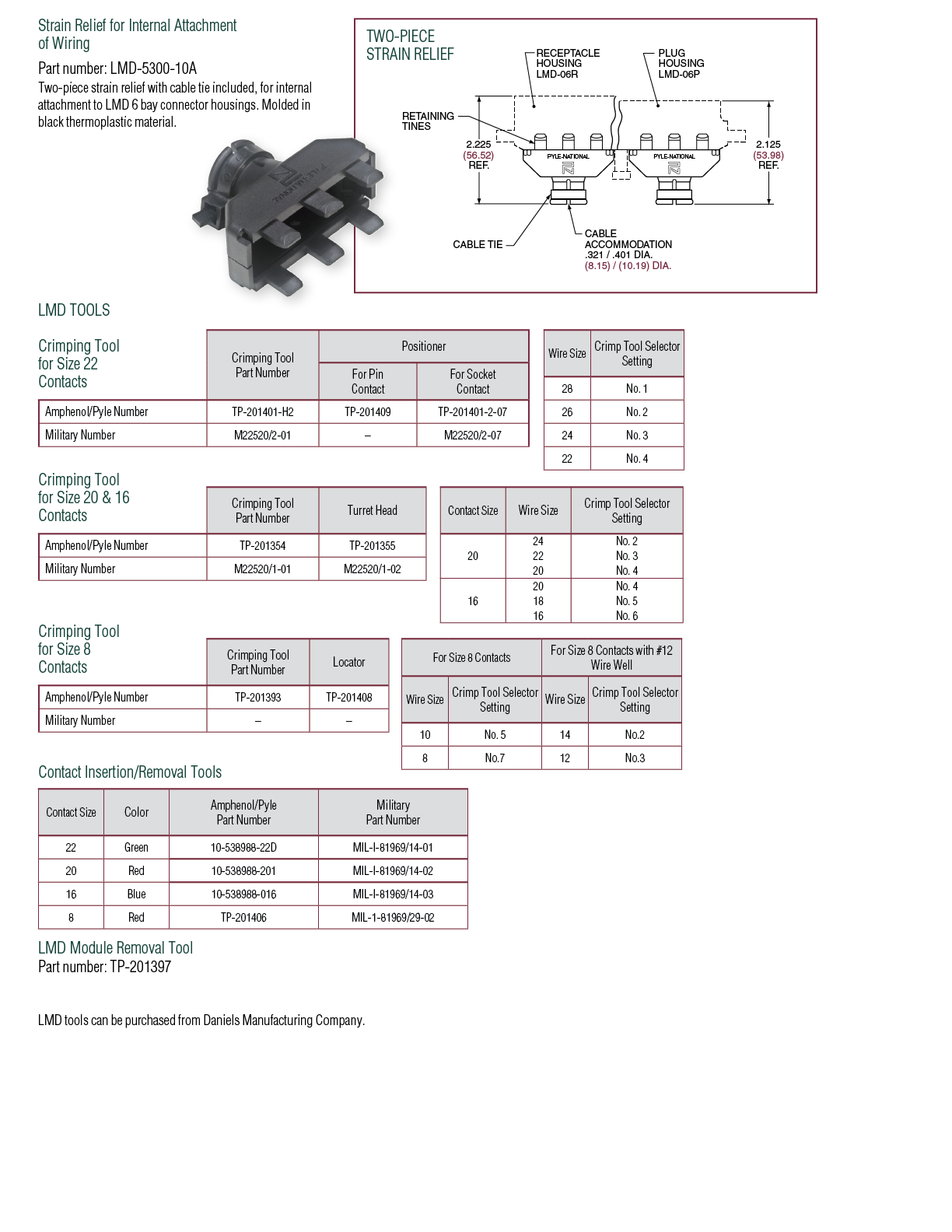

Description:

The LMD Connector Series was designed by Amphenol to provide flexibility in the assembly of wire harnesses that are used in instrumentation and avionic control environments. The modular design of the LMD provides rack and panel or cable to cable attachment.

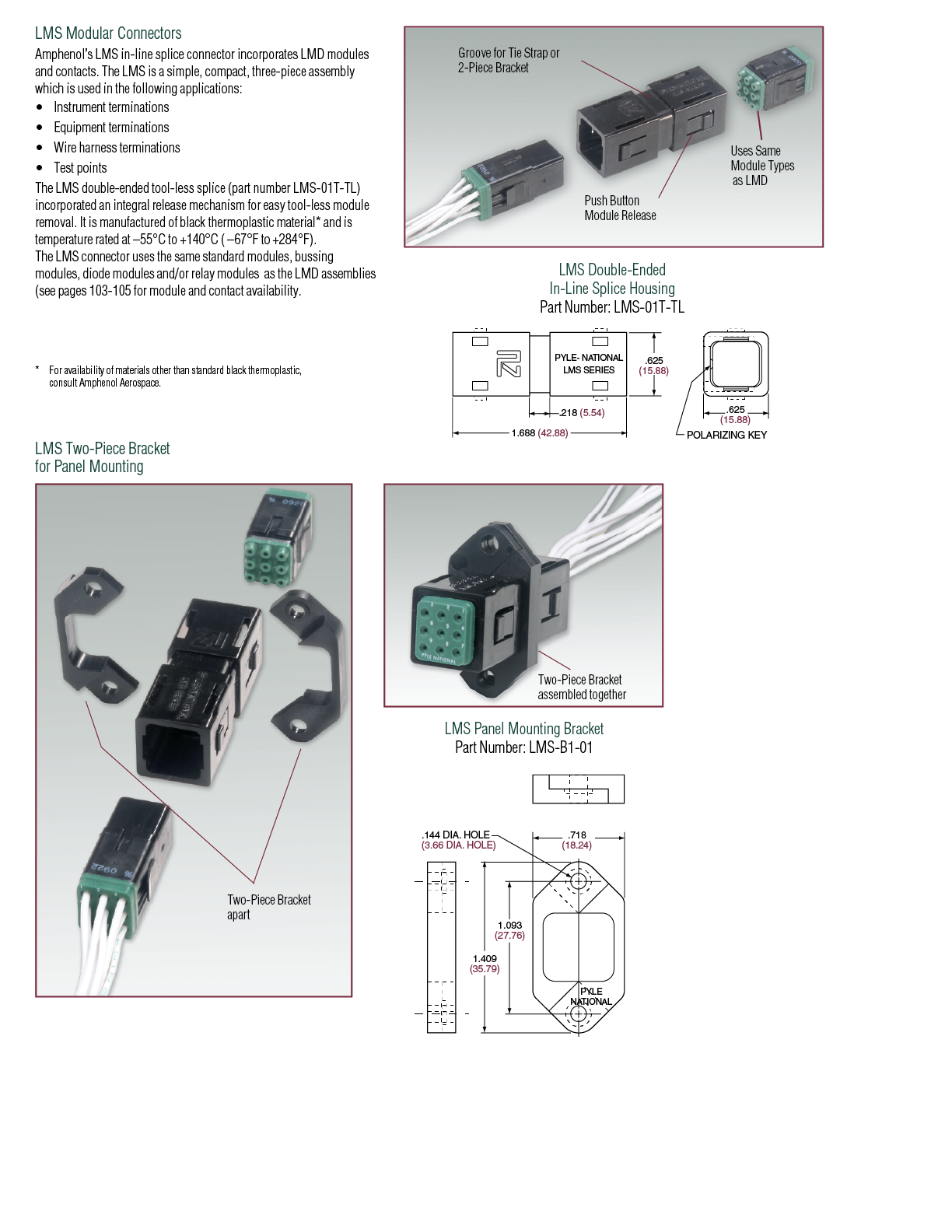

Supplementing the LMD connector family, the LMS in-line splice connector; a low cost interconnects that incorporates the LMD modules and contacts.

Features & Benefits:

- Reduces assembly and production costs

- Eliminates costly PC board and associated hardware

- Reduces inventory levels and associated costs

- Allows for a variety of circuit configurations

- Permits ease of circuit upgrading

- Facilitates equipment maintenance

More Information

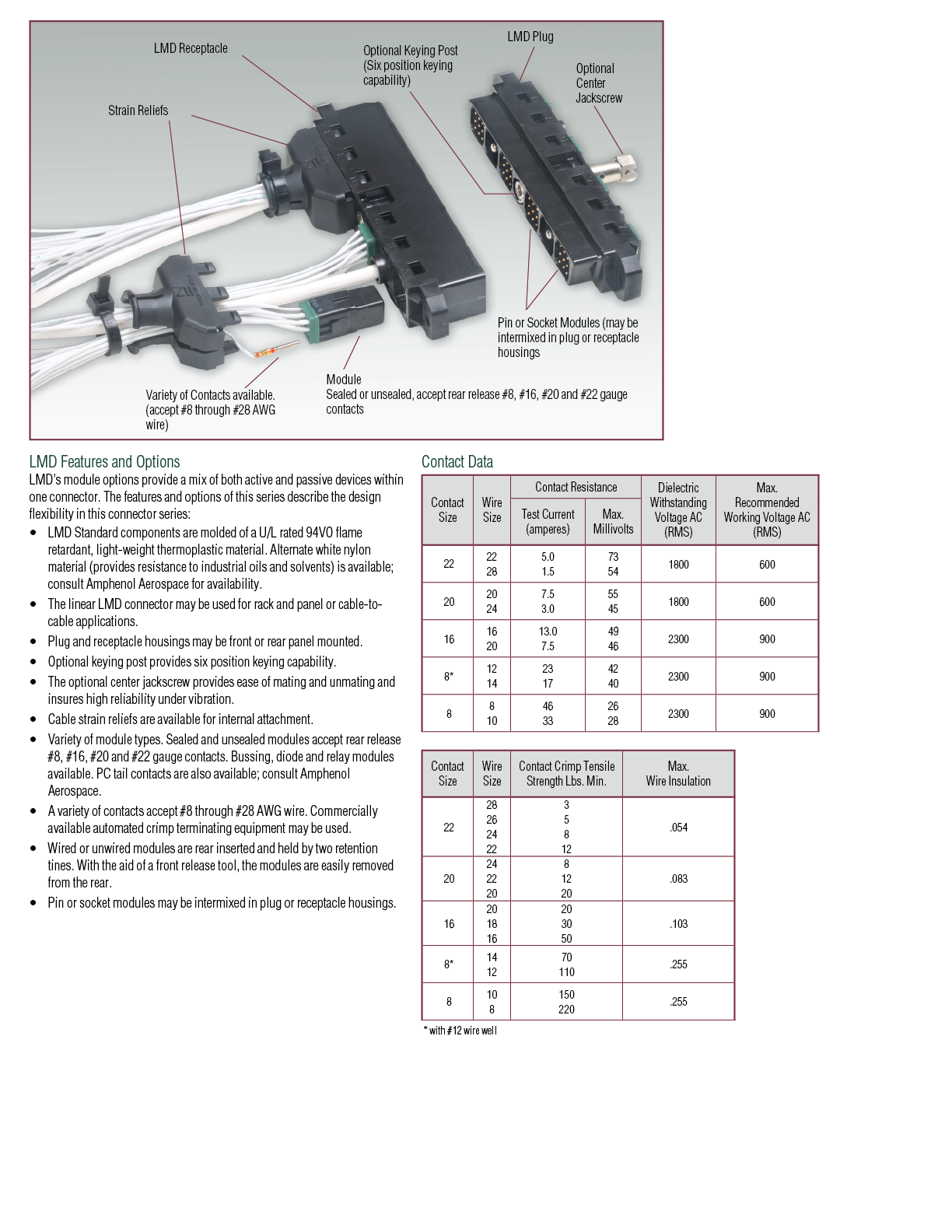

- LMD’s module options provide a mix of both active and passive devices within one connector.

- LMD Standard components are molded of a U/L rated 94VO flame retardant, light-weight thermoplastic material. Alternate white nylon material (provides resistance to industrial oils and solvents) is available.

- The linear LMD connector may be used for rack and panel or cable-to-cable applications.

- Plug and receptacle housings may be front or rear panel mounted.

- Optional keying post provides six-position keying capability.

- The optional center jackscrew provides ease of mating and unmating and ensures high reliability under vibration.

- Cable strain reliefs are available for internal attachment.

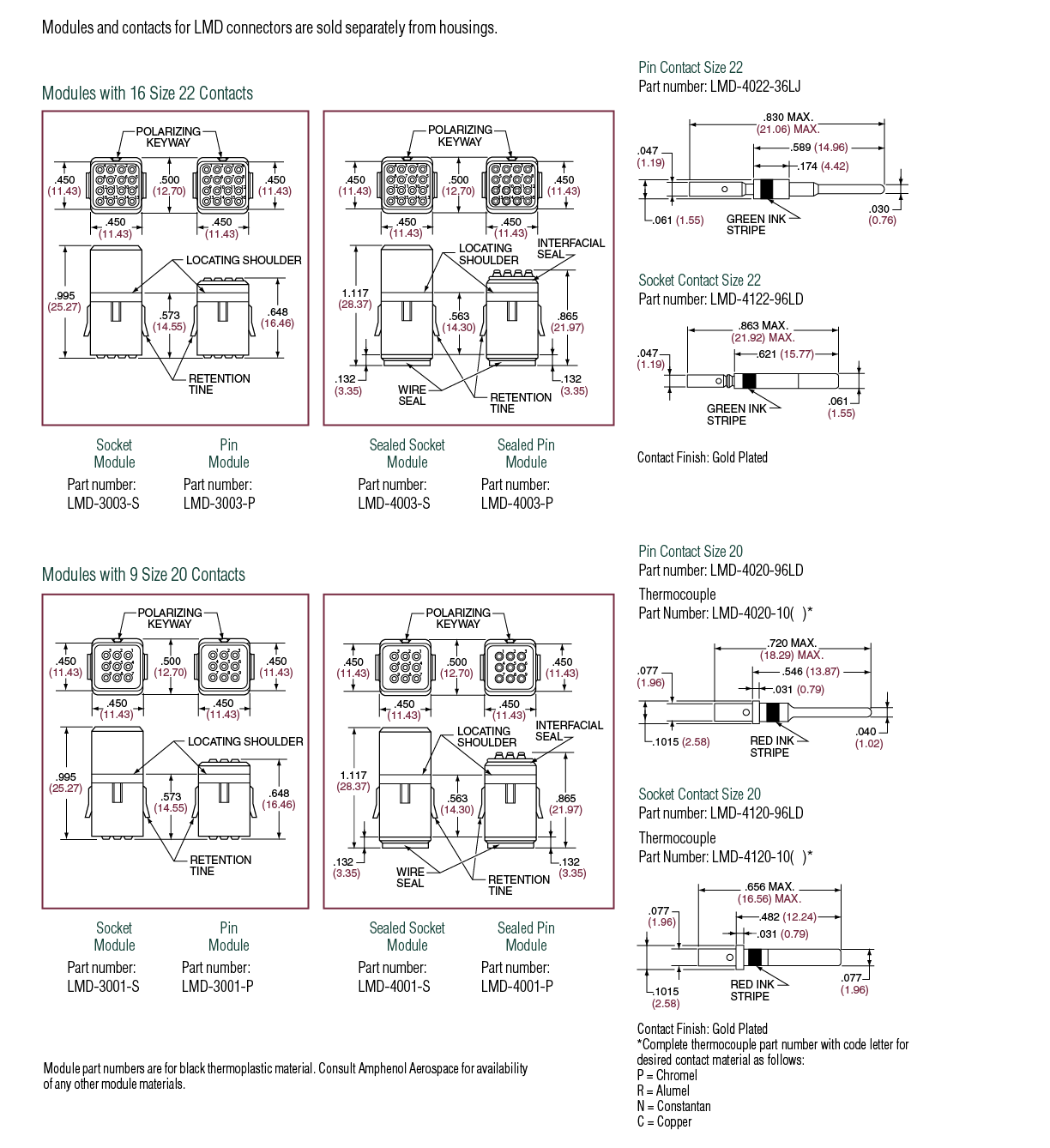

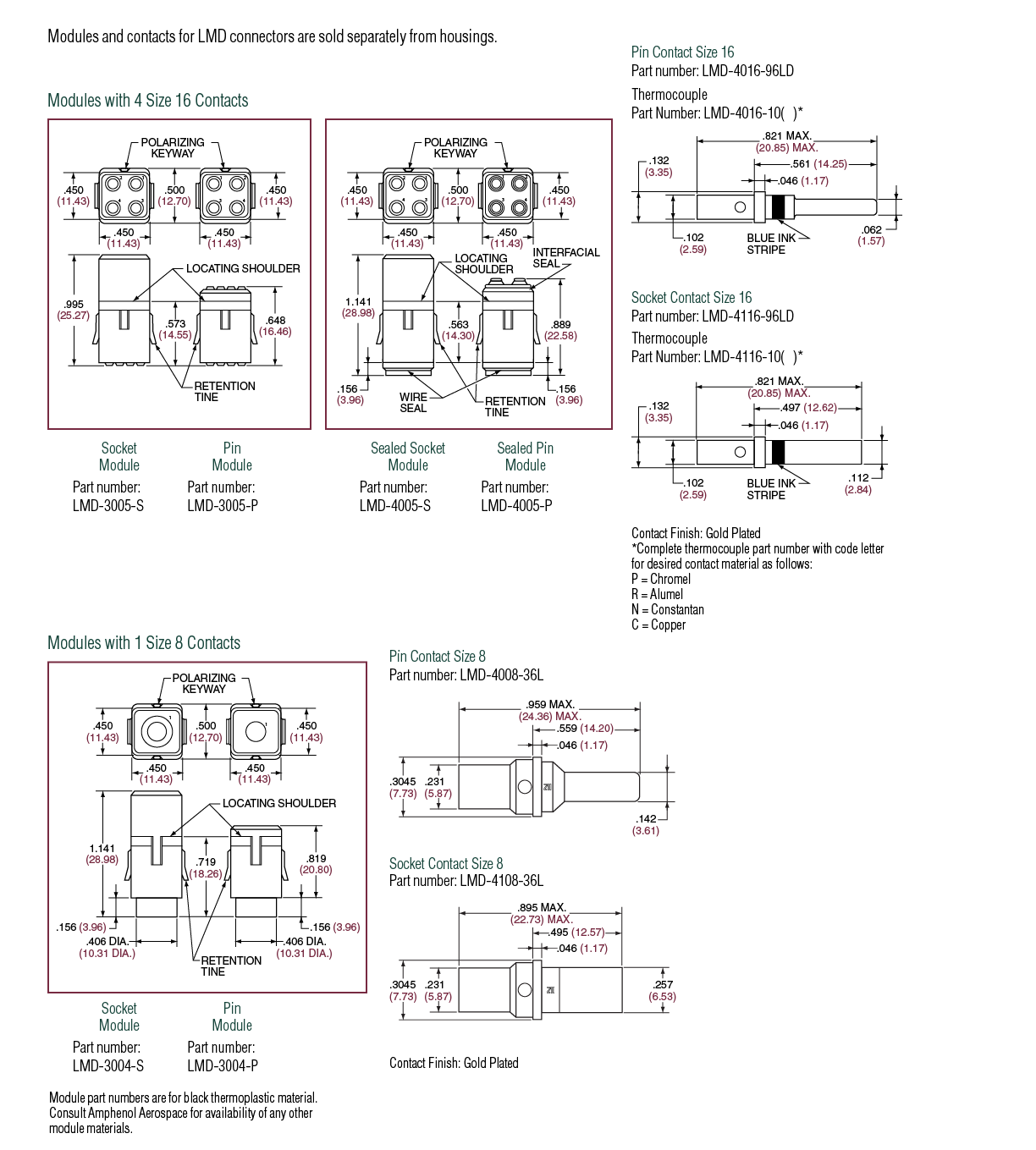

- Variety of module types. Sealed and unsealed modules accept rear release #8, #16, #20 and #22 gauge contacts. Bussing, diode and relay modules are available. PC tail contacts are also available.

- A variety of contacts accept #8 through #28 AWG wire. Commercially available automated crimp terminating equipment may be used.

- Wired or unwired modules are rear inserted and held by two retention tines. With the aid of a front release tool, the modules are easily removed from the rear.

- Pin or socket modules may be intermixed in plug or receptacle housings.

Performance Specifications

| Temperature Rating | -55°C to +140°C (-67°F to +284°F) |

| Insulation Resistance (min.) | 5000 megohms initial: 1000 megohms after 96 hours humidity |

| Durability | 250 cycles (mating and unmating) |

| Vibration | Maximum discontinuity of one microsecond when subjected to sinusoidal vibration of 10 to 2000 Hz at 15 gravity units |

| Physical Shock | Maximum discontinuity of one microsecond when subjected to 1/2-sine-wave transient shock of 50 gravity units with pulse duration of 11 milliseconds |

| Module Insertion & Removal Force | 5 lbs. maximum |

| Module Retention | 70 lbs. minimum |

Connector Options

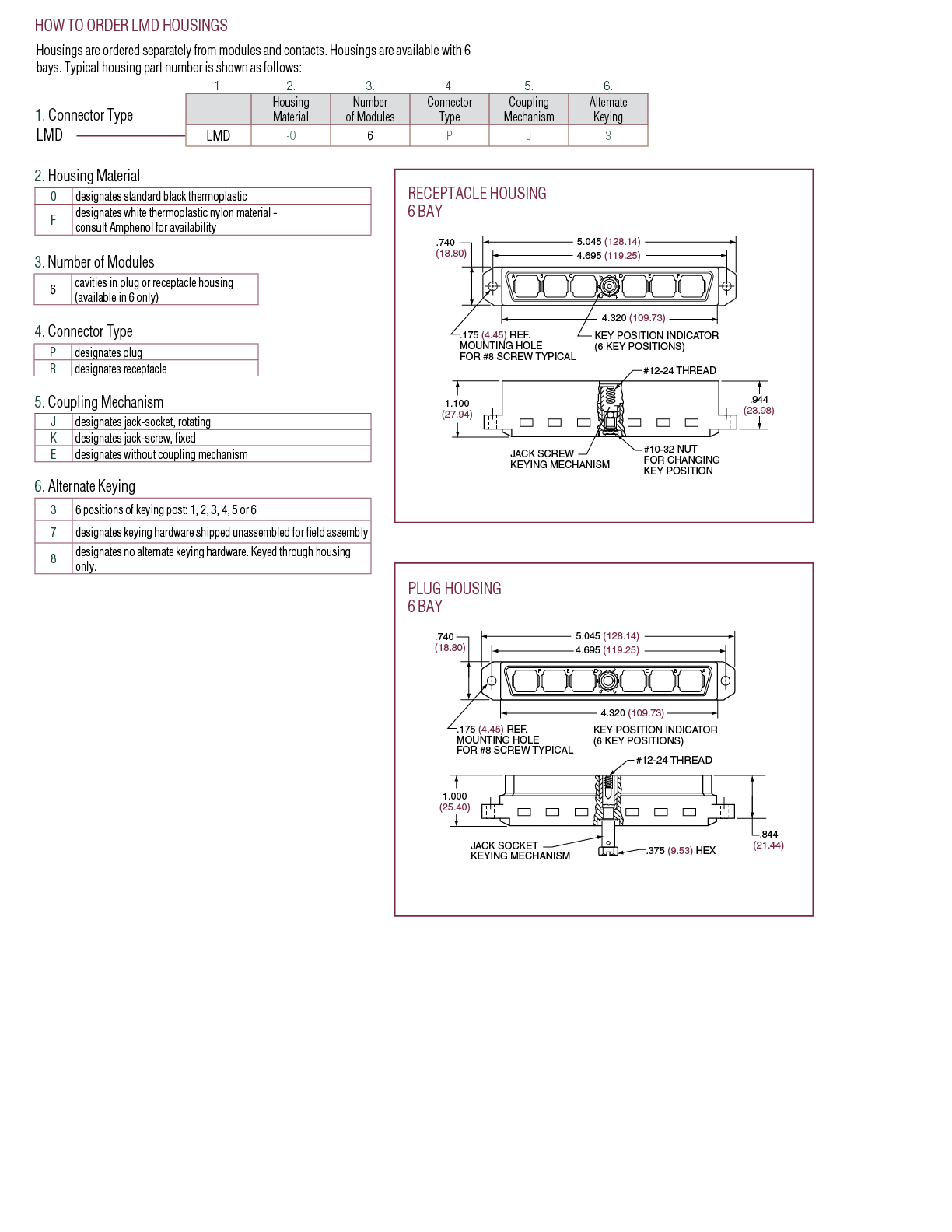

LMD Dimensions and Order Guide

Module Contact Arrangements

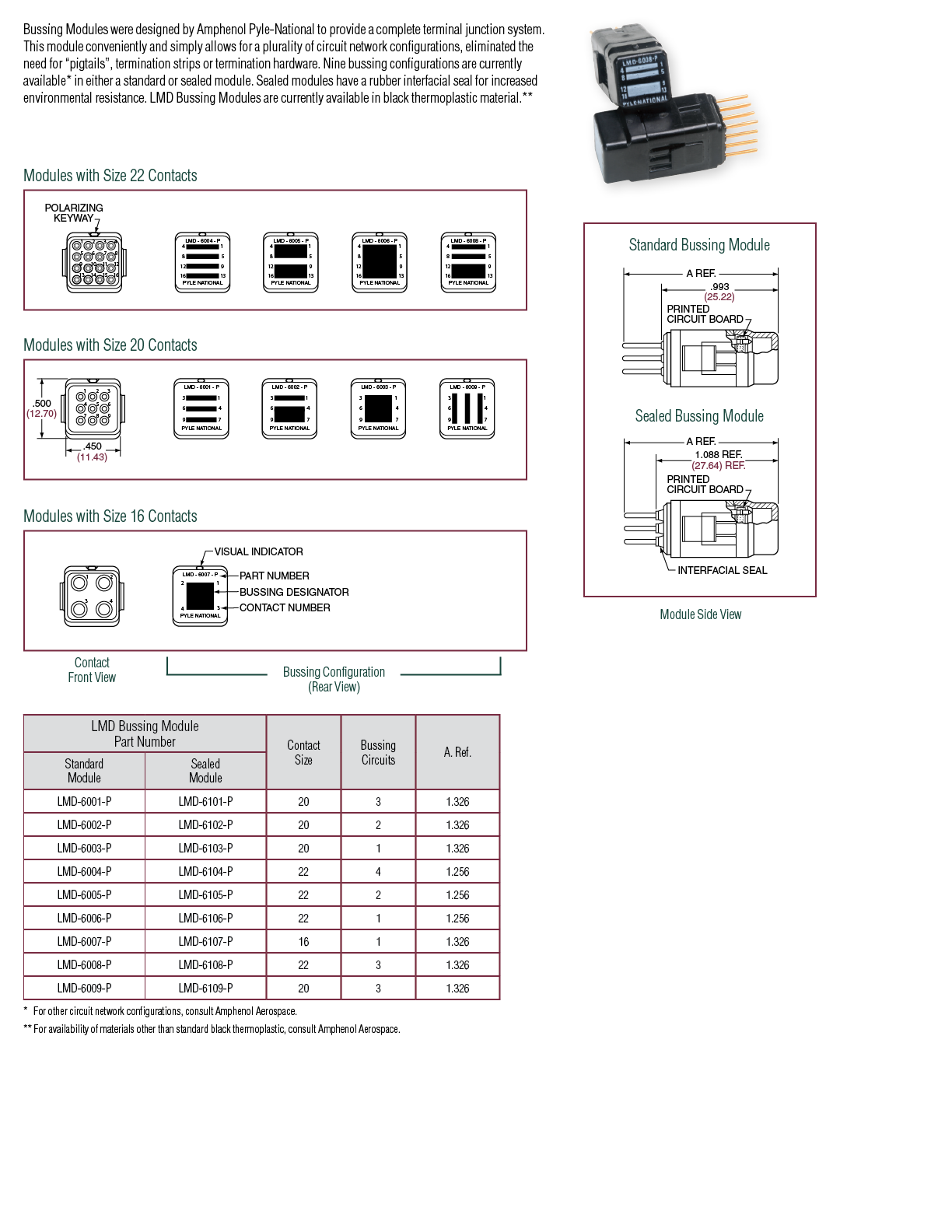

Bussing Modules

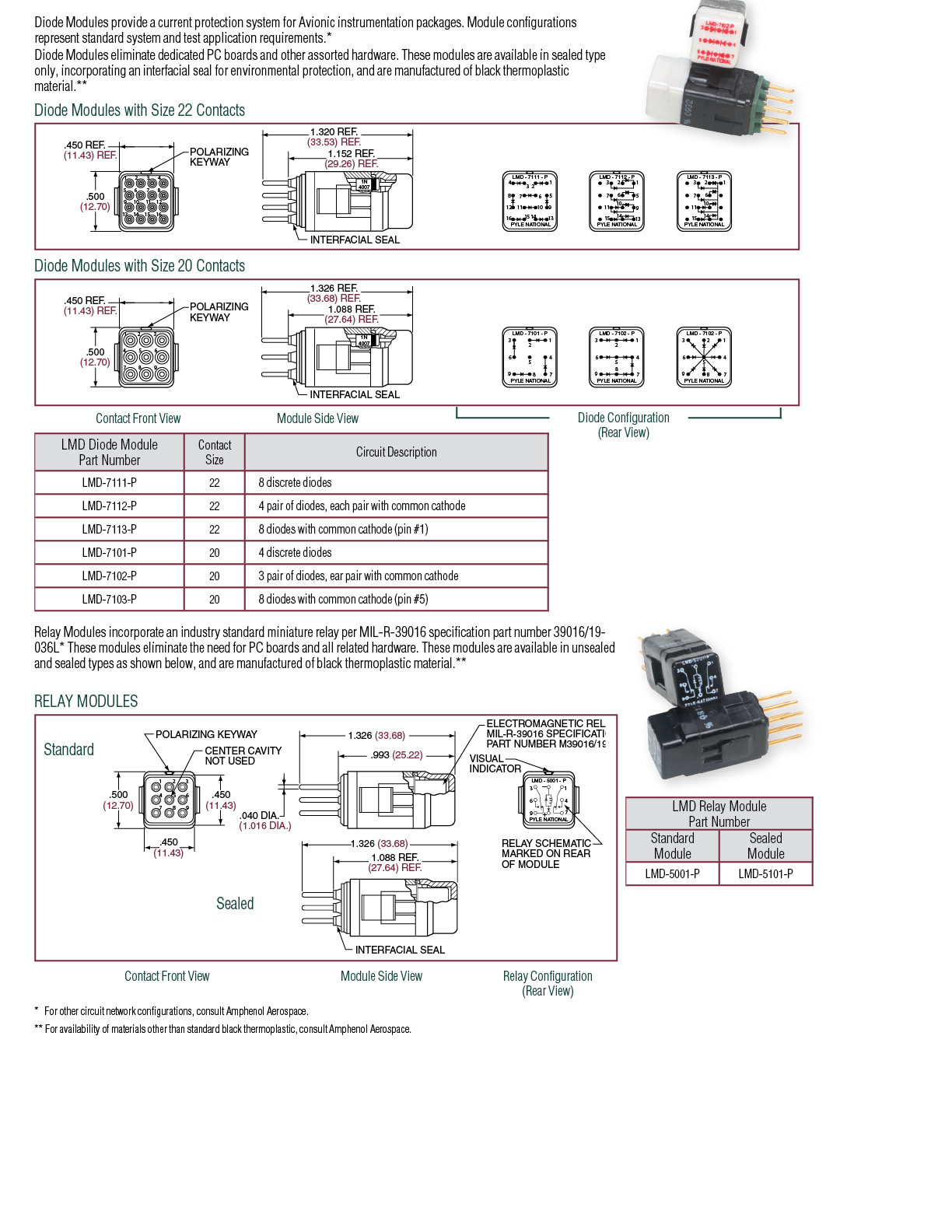

Diode Modules and Relay Modules

LMS In-Line Splice

Accessories

Assembly Instructions

EN4165 SIM Connectors

Modular, multi-functional rectangular connectors geared towards the US Com-Air and Military markets. Comprised of shells and modules, they are an integrated solution for advanced signal and power requirements – all at a fraction of the space typically required for the same results.

3559 Push-Pull Connectors

The 3559 Connector Series is a mono-modular, push-pull connector that is ideal for In-Flight Entertainment Systems, Cabin Service Systems, and other interconnect system requirements.

Solaris Series

A small, plastic, easy-to-use rectangular connector designed specifically for low and medium power applications.