Pyle 26500 Hermetic

Contact:

Description:

Amphenol Pyle 26500 Hermetic connectors are extremely durable and reliably serve a diverse range of fields such as avionics, missile systems, aircraft engines, and firewalls. These connectors meet MIL-DTL-26500 Class H hermetic specifications and feature the same rugged design, lightweight construction, and performance demands as our standard Pyle 26500 connector.

The 26500 Hermetic comes with the option of threaded or bayonet coupling and can sustain a significant portion of yield strength at extreme temperatures.

Features & Benefits:

- Hermetic sealing rated at 1x10-7 cc/sec helium.

- CRES stainless steel shell provides superior strength and corrosion-resistant characteristics

- Threaded or bayonet coupling

- Square flange, solder mount, or single-hole receptacles

- Shells experience a less than 10% loss in yield strength at elevated temperatures, 399 °F (204 °C)

- Non-magnetic stainless steel shells designed for superior strength and elevated temperatures up to 460°F for extended periods

- Low-profile design for restricted installation requirements

Tips for Customizing Hermetics

- How many Contacts?

Consider including a number of redundant contacts to accommodate any system developments you have planned for the future, or to comply with specified growth provisions. - What are the electrical requirements?

Work out a steady state and peak requirement for both the current and voltage. - Will your Glass-to-Metal Sealing be under any pressure?

Depending on the medium (for example, oil, water, or a vacuum) there may be a pressure differential to consider. Glass-to-Metal Sealing (GTMS) can be supplied in multi-pin preforms or, for high pressure applications in individual glass beads. - How will your GTMS be attached?

Will it be secured with a standard O-ring, for example, or welded in place? - What are your cable interface requirements?

Be sure to include any instructions for screen termination, potting requirements, and/or cable strain relief. - Do you require custom functionality?

If you have any specific requirements, such as electromagnetic compatibility (EMC) filters or printed circuit board (PCB) mounting, make sure they are included in your design specification. - What are your plating requirements?

We offer a wide range of in-house plating options, including tin, nickel, and hard and soft gold. We can also customize the plating to meet any special requirements. Note that gold-plated solder contacts should either be desoldered before installation or appropriate plating thickness specified, to avoid solder embrittlement. - Are there any environmental factors?

If your application will be operating in a harsh or hostile environment (exposed to shock, vibration, thermal changes or extreme temperatures, for example) these will need to be factored into the design. - What are the qualification requirements?

If qualification tests are required, these should be discussed and specified during the design phase. We are able to perform most qualification tests on the appropriate levels of assembly. - What testing will you need?

Examples include leak testing, pressure testing, and geometrical and electrical testing; including breakdown, voltage, and insulation resistance of finished parts. - Cabling and wiring too?

If you would like to extend your brief to include your cabling and wiring requirements, we can address those as well.

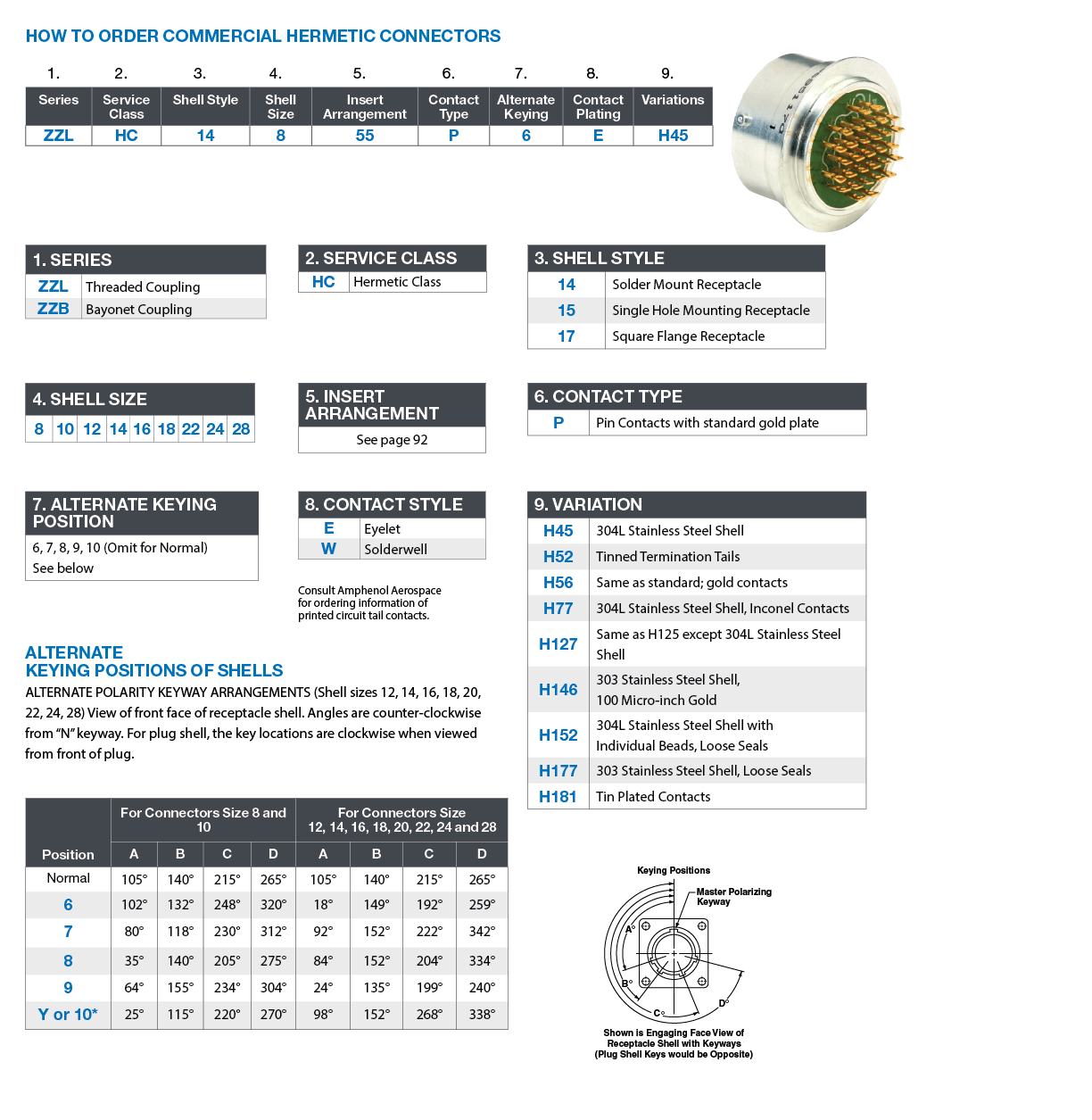

How to Order Guide

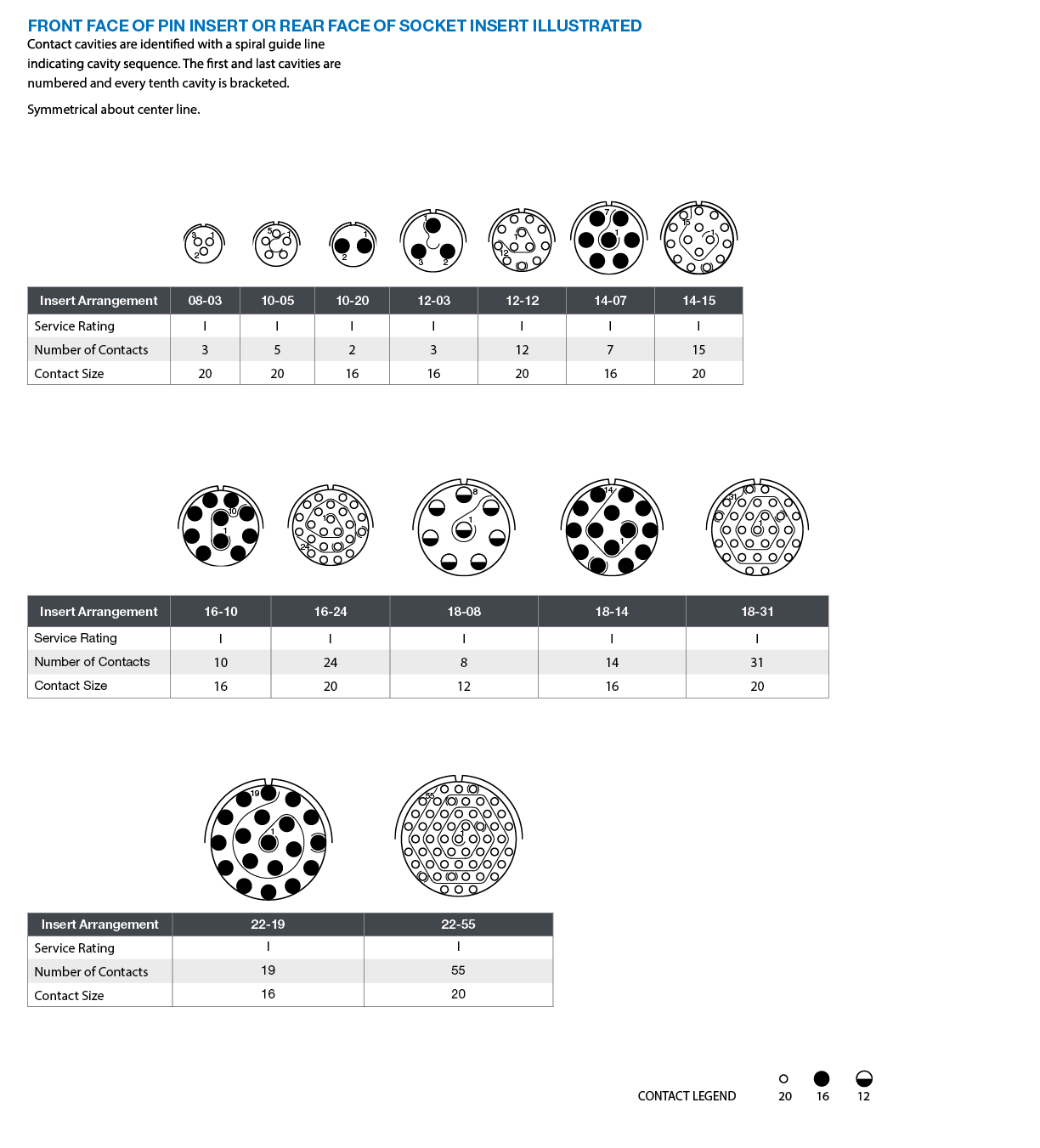

Insert Arrangements

Pyle 26500

Medium-sized connectors with a rugged design, lightweight construction, and continuously dependable performance.

Electro-Mechanical Integration

Building complex assemblies requires a robust quality system, strong engineering support, and world class operators.

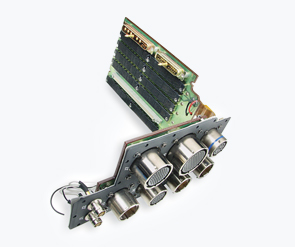

Flex/Rigid Flex

Flex and rigid-flex circuitry offer many advantages when considering the most effective means to transmit signals or power within your system.

Advanced Assemblies

Large format, high component count, complex assemblies for the aerospace and communication industries that require surface mount, thru-hole or press-fit assembly processes.

Pressure Sensors

Use piezoresistive technology for its sensor signal processing to measure pressure.

Aerospace Sensors

An array of standard and customized sensing solutions to provide the most reliable and accurate performing solutions for the most stringent of Aerospace applications.