Advancements in robotics technology have already proven their significance in space exploration with programs such as the Mars rovers and the International Space Station. As NASA seeks to return humans to the moon this decade, robotics will be fundamental to the success of future lunar missions too. Their use will only continue to grow as we expand our footprint on the moon.

Lunar Exploration

A main area where robotics will be instrumental is in the exploration and surveying of the lunar surface. Robotic rovers equipped with advanced sensors and cameras can be deployed to collect data, capture images, analyze lunar terrain, and more. These rovers can navigate rough and challenging terrains that would be difficult for human astronauts to traverse safely. By gathering detailed information about the lunar surface, robotic explorers can assist in identifying suitable landing sites, locating resources, and planning future missions effectively.

One series of rovers under development that have been tasked to do this are NASA’s Cooperative Autonomous Distributed Robotic Exploration (CADRE) rovers. These shoebox-sized robotic scouts are being designed to work as a team and autonomously explore the moon, Mars, and other celestial bodies. Each system is outfitted with onboard computers, wireless radios and cameras with image sensors that enable them to navigate the surrounding environment, and they’re capable of traveling across very difficult terrain without the direction of a human operator.

The concept behind the CADRE rovers is that a group of them can work together to collect data about their observations. This could prove very useful in hard-to-reach areas of the moon that have been earmarked for exploration, such as the moon’s lava tubes, craters and caves. The information gathered by the rovers would then be relayed back to a base station on the lunar lander.

The Lunar Vertex, another exploration rover, will be tasked with exploring the mysterious lunar swirls that cover the moon’s surface. This rover will explore Reiner Gamma, one of the most prominent lunar swirls on the moon.

The beautiful lunar swirls have long intrigued scientists. Their lack of surface definition and elevation mean the swirls don’t cast shadows, and their origin is a mystery. The Lunar Vertex rover will take magnetic and spectral measurements to learn more about these formations.

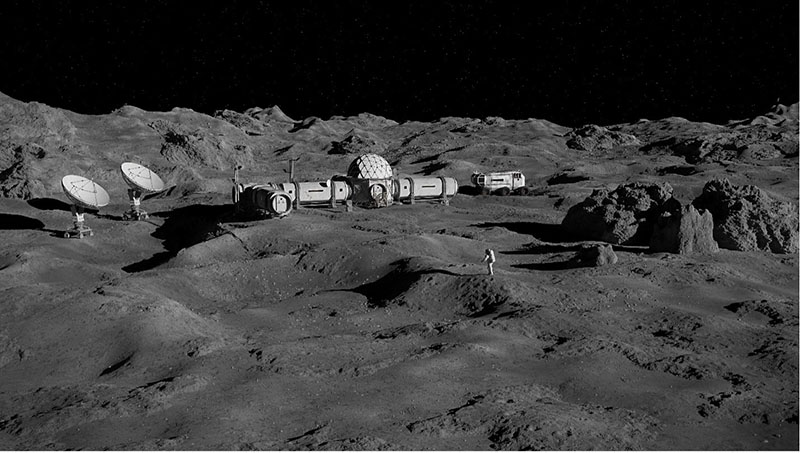

Lunar Construction

Robotics will also play a vital role in the construction and maintenance of lunar infrastructure. Autonomous or remotely operated robotic systems can be utilized to perform tasks such as assembling habitats, setting up solar panels, and building infrastructure for scientific experiments. By deploying robots for these activities, the risks and costs associated with human involvement can be reduced while ensuring that the necessary groundwork is completed efficiently.

Robotics have been used in space throughout the last several decades. One of the most prominent examples is the Canadarm, a robotic arm manufactured in Canada that was a pioneer in space robotics when it was launched with the first Space Shuttle mission in 1981.

Canadarm2 was deployed to the International Space Station in 2001 and has become an integral system on the ISS, while Canadarm3 is slated to deploy on the Lunar Gateway. The Gateway is a future lunar orbiting space station integral to NASA’s Artemis Program, and Canadarm3 is expected to assist with its construction, maintenance, and repair.

NASA foresees the Artemis Program leading to the creation of a lunar base and sustainable human presence on the moon. Robotics are expected to play a major role in the base’s construction when it comes time to build it.

Developing robotics with in-space servicing, assembly, and manufacturing (ISAM) capabilities is a high priority with NASA. The space agency announced in April the creation of a new consortium dedicated to ISAM called the COnsortium for Space Mobility and ISAM Capabilities (COSMIC).

Moon Mining

A lunar base and a sustainable human presence on the moon will not be possible without lunar mining.

Vast amounts of resources will be required to construct a permanent lunar habitat and sustain the life support systems that astronauts will require up there. But there’s only so much you can pack and take with you into space.

Despite its barren appearance, the moon possesses various natural resources. One of the most significant of these resources is water ice, which is believed to exist in significant quantities in the permanently shadowed regions near the moon's poles. Water ice can be used to produce drinking water, breathable oxygen, and serve as a vital resource for fuel production.

The lunar soil also contains a variety of other valuable metals, minerals and elements including titanium, a metal known for its strength, corrosion resistance, and light weight with applications in aerospace, medicine, and other industries; silicon, which is a crucial element in the production of solar panels, electronics, and various other applications; and helium-3, a valuable isotope that has potential applications in fusion energy research.

Robotics are slated to play a variety of important roles on the moon in the near future. But for robotics to effectively execute their missions on the lunar surface, they’ll need to overcome the challenges posed by lunar regolith and dust – an unapparent but serious obstacle to lunar missions.

What is Lunar Regolith?

Lunar regolith is the loose, unconsolidated layer of debris that covers the lunar surface. The Apollo missions of the late 1960s and early 1970s found lunar regolith, and the lunar dust within it, to be a major issue.

Lunar dust, which consists of fine, jagged particles within lunar regolith such as basalt and glass, tends to adhere to all sorts of material and surfaces from spacesuits to metal due to its electrostatic properties. It is incredibly abrasive and has poor thermal conductivity, which risks causing equipment failure.

And because it is electrostatic, lunar dust undergoes photoelectric charging by solar winds. Combined with the moon’s low-gravity environment, this causes the dust to remain suspended above the lunar surface for extended periods of time if it is stirred up on the ground.

Lunar dust gets everywhere. And when it does it can cause huge problems. Further human exploration of the moon will require significantly mitigating the complications and risks posed by this material.

“One of the most aggravating, restricting facets of lunar surface exploration is the dust and its adherence to everything no matter what kind of material, whether it be skin, suit material, metal, no matter what it be and its restrictive friction-like action to everything it gets on,” said former NASA astronaut Eugene Cernan, a crewmember aboard Apollo 17.

Amphenol Aerospace recognizes the need to develop a highly reliable lunar electrical connector to promote the efficiency, dust resistance, and overall safety of future systems that operate on the lunar surface. Amphenol bristle brush contacts were an ideal starting point for developing this connector.

Why Bristle Brush Contacts?

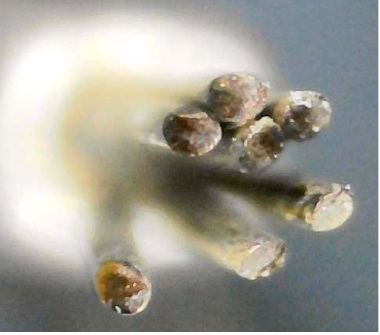

Bristle brush contacts consist of strands of high tensile wire bundled together that operate by intermeshing two multi-strand wire bundles until a connection is made.

These highly reliable contacts meet MIL-DTL-55302 requirements and have proven themselves for more than 30 years in military avionics systems and other harsh-environment applications. They are versatile and durable due to their low mating force and redundant mating surfaces and are qualified in sand and dust environments.

Our bristle brush contacts were tested with LSM-1 Lunar Regolith Simulant, which mimics the texture and consistency of lunar regolith material. The contacts were coated with the simulant in a variety of different intervals and tested for connectivity strength.

The tests revealed that coating the contacts in lunar regolith to mimic lunar conditions had a variety of negative effects on their performance, including increases in electrical resistance and engagement force. It was apparent that a different type of brush contact system was necessary to overcome the unique challenges posed by lunar regolith material.

Sign up below for more insights into our lunar simulant testing and to learn more about the development of our lunar regolith connector, which features a proprietary and reimagined brush contact design that ensures abrasive lunar regolith won’t interfere with critical lunar systems.