By Stephen Borgna

Marketing Communications Specialist

Looking toward the future, optimizing size, weight, power, and cost (SWaP-C) throughout military and aerospace applications will be more important than ever. Fighter jets have shed size and weight, ground vehicles have adopted lighter components and sleeker dimensions, and space vehicles and satellites have continued to prioritize weight and size minimalism.

Large, heavy military aircraft, ships, and ground vehicles are slower, bulkier, and less maneuverable. Every pound of weight and every inch of space saved can lead to efficiencies in other areas such as increased maneuverability, occupant carrying capacity, weapons, and equipment. In short, every ounce matters.

SWaP-C Before It Had a Name

A General Dynamics YF-16 and Northrop YF-17 − prototypes of the F-16 and F/A-18, respectively −fly in formation during the U.S. Air Force’s Lightweight Fighter Program of the 1970s.

Size, weight, power, and cost – before it was recognized by the acronym SWaP-C – were always considerations when developing new military and aerospace technologies. But one of the earlier examples when industry began to harp on this philosophy was in the mid-to-late 20th century as fourth-generation fighter programs began to take flight.

During the Vietnam War, the U.S. Air Force flew third-generation fighter aircraft such as the McDonnell Douglas F-4 Phantom and the General Dynamics F-111 Aardvark. However, while these fighters were fast, they were also very heavy and very bulky, as per the design philosophies of the time. The Aardvark itself weighed more than 100,000 pounds fully loaded.

In air combat with North Vietnamese MiG-17s and MiG-21s over Vietnam, aircraft like the Phantom performed well at longer ranges using radar- and infrared-guided missiles but often struggled in shorter range engagements. The F-4’s AIM-7 and AIM-9 air-to-air missiles were unreliable early in the war, and the fast but brawny Phantom lacked a gun until the late 1960s when it became clear that close range dogfighting wasn’t going away, despite assumptions that radar-guided and heat-seeking missiles would dominate future air combat. Externally mounted gun pods and, later, the F-4E’s internal M61 cannon improved the platform’s dogfighting capabilities. But its large size, high wing loading, and smoky twin engines still held it back compared to the lighter, more agile MiGs despite the F-4’s prowess as an interceptor and a fighter bomber.

Large third-generation fighters like the F-4 Phantom were successful as interceptors and fighter bombers but had flaws in short-range air-to-air combat during the Vietnam War.

The U.S. averaged roughly a 2.5:1 kill ratio in air-to-air combat throughout the Vietnam War, which means that about 2.5 enemy aircraft were shot down for every U.S. aircraft lost. For comparison, the Air Force averaged about a 10:1 kill ratio during combat over Korea the decade prior.

The dogfighting growing pains experienced by American pilots over Vietnam didn’t go unnoticed. The Navy, for instance, established the Top Gun school in 1969 to train its pilots in the lost art of dogfighting after enduring heavy losses. Navy pilots subsequently began to perform better in air-to-air battles than their Air Force peers.

But the reality of the situation also caught the attention of a small but vocal group of officers, defense analysts, and former pilots in the Pentagon. Citing American air losses over Vietnam, this group was critical of the large and complex fighter platforms that made up the core of the Air Force’s fleets. They believed in developing a new type of fighter to replace them, one that harkened back to the spirit of World War II aircraft with a platform that emphasized low weight, high thrust-to-weight ratios, and agility in close combat rather than heavy, multirole platforms. These fighters would ideally be simpler to fly, discarding a lot of the advanced features of the time in favor of a minimalist platform with a pared-down radar or even no radar at all, and limited avionics. They would only carry guns and simple air-to-air missiles, be designed solely to establish air superiority, and be easy to produce and field in large numbers.

This group became known as the Fighter Mafia, a term coined by their critics, and their ideas were considered radical for the time.

The Lightweight Fighter Program of the 1970s brought some of these ideas to life. The General Dynamics YF-16 and Northrop YF-17 prototypes embodied the philosophy of smaller, lighter, and more agile fighters that could be built in greater numbers at lower cost. Both designs prioritized thrust-to-weight ratio, agility, and simplicity over size and complexity. Together, they gave rise to two of the most successful fourth-generation fighters in history, the F-16 Fighting Falcon and the F/A-18 Hornet.

A General Dynamics YF-16 prototype (top) flies in formation with a McDonnell Douglas F-4C Phantom II in 1976. Notice the size difference—a key distinction between third- and fourth-generation aircraft, with the former placing greater emphasis on what we now refer to as SWaP-C principles.

The Fighter Mafia didn’t get everything they wanted. The F-16 and F/A-18 were both designed as multirole fighters with advanced radars, avionics, and weapons delivery systems, contrary to the group’s minimalist philosophy. But their ideas left a lasting impression on U.S. fighter design. In hindsight, these programs were among the earliest demonstrations of what we now call SWaP-C optimization: using weight and size reductions to unlock greater overall capability.

Modern systems have embraced SWaP-C principles in the years that followed, such as the Army’s embrace of lighter armored vehicles like the Stryker family and the Department of Defense’s pivot toward the Modular Open Systems Approach (MOSA) in the 2010s. Both trends reflect the same design imperative: reduce size, weight, and cost while increasing flexibility and capability.

Just as the Lightweight Fighter Program proved the value of smaller, lighter platforms, connectors today must embody the same principles at the subsystem level.

Connectors Built for SWaP-C

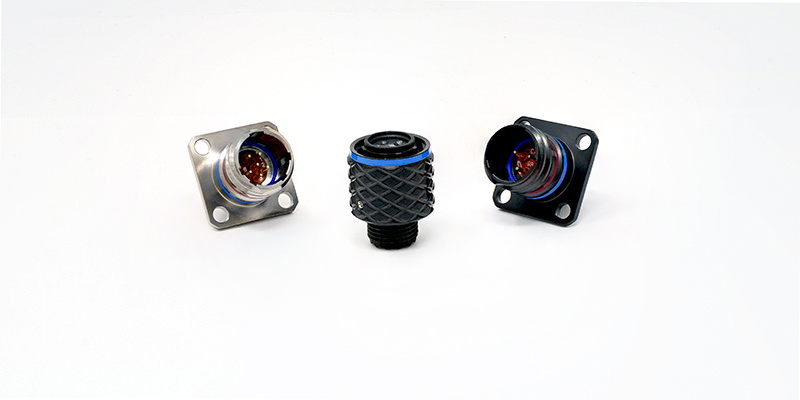

Amphenol’s 2M family of harsh environment circular connectors is designed to meet modern SWaP-C parameters while delivering the same performance as MIL-DTL-38999.

Interconnects may be small components in the broader system architecture, but they sit at critical junctions where size, weight, power, and cost pressures converge. SWaP-C demands are only going to grow in the decades ahead as sixth-generation aircraft, hypersonic delivery systems, and other next-generation platforms come online, making it imperative that subsystem architectures follow suit. Amphenol Aerospace’s 2M and Series Five connectors were engineered with these considerations in mind: miniaturized, lightweight, and versatile interconnect solutions that enable modern defense and aerospace platforms to meet aggressive SWaP-C targets without sacrificing rugged performance.

Compact Size and High-Density Designs

Amphenol Series Five is up to 20% smaller and up to 50% lighter than MIL-DTL-38999 Series III with higher voltage capabilities.

Every fraction of an inch and ounce matters in the crowded and weight-sensitive environments of modern military and aerospace system architectures. Amphenol’s Series Five and 2M connector families address these challenges with significant miniaturization and contact efficiency.

Series Five, a miniaturized connector series that builds on the MIL-DTL-38999 spec of connectors, trims roughly 20% off the size and up to 50% off the weight of traditional D38999 Series III connectors while sustaining equivalent environmental performance and providing higher voltage capabilities. This makes it especially suitable for applications like UAVs, satellites, and portable defense systems that demand ruggedness and compactness in equal measure.

Meanwhile, Amphenol’s 2M micro‑miniature line pushes miniaturization even further, achieving 71% weight reduction, 52% smaller physical size, and 60% greater contact density than MIL‑DTL‑38999 counterparts. 2M also is offered packaged in a selection of different derivatives. With options like the 2M Hermetic, for example, designers gain sub‑half‑scale solutions with full hermetic sealing for advanced avionics and harsh‑environment gear.

Together, these connector families epitomize the SWaP‑C ethos—shrinking size and mass without sacrificing performance. That translates directly into more onboard capability, longer mission endurance, and leaner, higher‑performing systems overall.

Lightweight Materials and Rugged Performance

Amphenol 2M805 High Vibration Connectors are designed to meet the severe vibration requirements outlined in the MIL-DTL-38999 specification.

Defense and aerospace systems face punishing heat, cold, vibration, shock, and exposure to dust, moisture, and corrosive elements in their operating environments. Connectors in next-generation systems must be designed to endure all of this while adding as little weight as possible. Amphenol’s Series Five and 2M families strike this balance by using advanced lightweight materials and ruggedized construction to ensure reliability in the field without adding unnecessary mass to the platform.

Series Five connectors employ engineered aluminum alloys and precision-machined shells that cut overall weight compared to traditional MIL-DTL-38999 connectors. Even with this weight reduction, they preserve the rugged characteristics that military systems demand, including EMI shielding, fluid resistance, and mechanical integrity under vibration. Variants such as the Series Five High Temperature Series go further, incorporating ceramic inserts and thermal-resistant seals capable of surviving the elevated heat of propulsion systems or engine bays, allowing them to withstand heat exposure at 572 °F (300 °C) for up to 24 hours and 500 °F (260 °C) continuous duty.

The 2M family takes a micro-miniature approach, but its toughness belies its small size. 2M connectors use high-strength alloys and corrosion-resistant finishes that perform reliably in salt fog, sand, and dust. Environmental sealing options, such as the hermetic 2M line, provide airtight protection down to helium leak rates measured at 1 × 10⁻⁸ cc/sec for long-term reliability in vacuum-sealed or pressure-sensitive applications. The mechanical endurance of the series is equally robust, with coupling mechanisms engineered to withstand thousands of mating cycles while maintaining contact integrity under extreme vibration and shock.

By combining lightweight shells with proven ruggedization techniques, both Series Five and 2M exemplify how SWaP-C optimization extends beyond size and density. They demonstrate that modern interconnects can shed mass without sacrificing the environmental resilience and mechanical performance demanded by next-generation military and aerospace platforms.

Power and Signal Versatility

Series Five High Temperature Connectors are designed to deliver connections in extremely high-heat environments, withstanding exposure at 572 °F (300 °C) for up to 24 hours and 500 °F (260 °C) continuous duty.

Modern defense and aerospace platforms rely on increasingly complex electronic architectures, blending high-speed data, low-level analog signals, and high-power distribution within the same system. Connectors must be capable of handling this diversity without adding unnecessary bulk or requiring multiple interconnect families. To address this, Amphenol’s Series Five and 2M lines offer configurations that can accommodate everything from high-amperage power contacts to high-density signal and data arrangements in a single compact package.

Series Five connectors are built to mirror the flexibility of traditional MIL-DTL-38999 systems while introducing meaningful SWaP-C improvements. They support a wide range of contact sizes that allow designers to mix power and signal within the same shell. Options include high-current contacts for systems demanding up to 23 amps per line, alongside low-level signal and coaxial contacts for data and RF. This versatility makes Series Five especially well-suited for next-generation avionics, radar systems, and vehicle electronics where combining multiple signal types into fewer connectors reduces both weight and wiring complexity.

The 2M micro-miniature series pushes this adaptability further by delivering high contact density in a dramatically smaller package. Designers can specify layouts that mix standard signal contacts with high-speed options such as twinax and quadrax for data rates up to several gigabits per second. Power contacts rated for 23 amps are also available, giving 2M the ability to support both demanding loads and sensitive electronics simultaneously. Specialized variants, such as 2M with fiber optic termini, extend this versatility to optical communications, while hermetic versions maintain performance even in vacuum-sealed or pressure-critical environments.

By consolidating power, signal, and high-speed data into a single connector family, Series Five and 2M simplify system architecture while delivering the electrical performance needed for modern defense platforms. This flexibility reduces connector count, minimizes cabling, and opens the door to lighter, more efficient, and more resilient system designs.

Cost Efficiency through Commonality

The 2M Space Saver right-angle EMI/RFI low-profile plug and backshell combination reduces the profile of your plug by 50% compared to a standard 2M801 while maintaining ruggedization and dependable shielding. This innovative micro-miniature combination significantly reduces space requirements without compromising ruggedness or performance.

Reducing size, weight, and complexity is only part of the SWaP-C equation. The “C” for cost is just as important, particularly as modern defense programs strive to maximize capability within constrained budgets. One of the most effective ways to reduce total system cost is through commonality—the use of connector families that share parts, tooling, and qualified components across multiple platforms. Amphenol’s Series Five and 2M product lines were developed to deliver meaningful cost efficiencies without sacrificing performance.

Series Five achieves cost savings by leveraging existing MIL-DTL-38999 ecosystem standards while streamlining the hardware itself. Because it maintains familiar insert arrangements and contact systems, engineers and technicians can reuse existing crimp tools, backshells, and accessories. This not only reduces procurement and training costs but also simplifies logistics, since the same support infrastructure applies across legacy D38999 and Series Five deployments. In other words, programs can transition to lighter, more compact connectors without overhauling their supply chain.

The 2M family provides similar advantages but in a micro-miniature format. Despite its smaller scale, 2M maintains cross-compatibility with AS39029 contacts and standard tooling, enabling cost-effective integration into new designs. Its broad range of insert arrangements further enhances commonality by allowing engineers to consolidate connector types across a platform. This reduces part numbers, streamlines maintenance, and lowers long-term sustainment costs. For programs managing large fleets of aircraft, vehicles, or space assets, that consolidation can translate directly into millions of dollars saved over the program lifecycle.

By designing Series Five and 2M around common components and industry-standard practices, Amphenol ensures that SWaP-C optimization extends beyond performance and into cost efficiency. This commonality enables defense and aerospace programs to modernize interconnect systems without incurring the penalties of unique tooling, specialized training, or fragmented supply chains, which makes every connector a long-term investment in both capability and affordability.