Electrification of Ground Combat Vehicles

Across a range of markets, electrification has become the name of the game, and ground combat vehicles are no exception. That means more electric vehicles, more electronic accessories, and more computers in every vehicle.

These new futuristic military vehicles are no longer simple machines. They’re outfitted with enough sensors and computing power to enable artificial intelligence to drive the vehicles on their own. They can react faster and keep us safer than we can without them. But with new technology comes new, unprecedented vehicle power requirements and that’s where we can help.

We’ve worked to keep up to date on what the military needs to support 600 volt DC systems in future ground vehicles. Since our current connector portfolio supports legacy vehicles’ 24 volt DC systems, understanding what’s changing in the vehicles is vitally important to our future power interconnect development.

New Ground Combat Vehicle Programs

When you think of power connectors on legacy ground systems and vehicles, you probably visualize the bulky, olive drab cadmium Class L MIL-DTL-22992 connectors. These, and other legacy products, service the needs of a 24 volt DC system used to power technology such as SINCGARS radios and basic radar systems.

Those connectors are more than enough to satisfy older system requirements. But with the evolution of new military vehicles such as the Joint Light Tactical Vehicle (JLTV) and the Next Generation Combat Vehicle (NGCV) variants, including the Robotic Combat Vehicle (RCV), Optionally Manned Fighting Vehicle (OMFV), Mobile Protected Firepower (MPF), and Decisive Lethality Platform (DLP), new power interconnect solutions are needed to support the 600 volt DC systems. There are three key reasons for the drastic increase in power requirements :

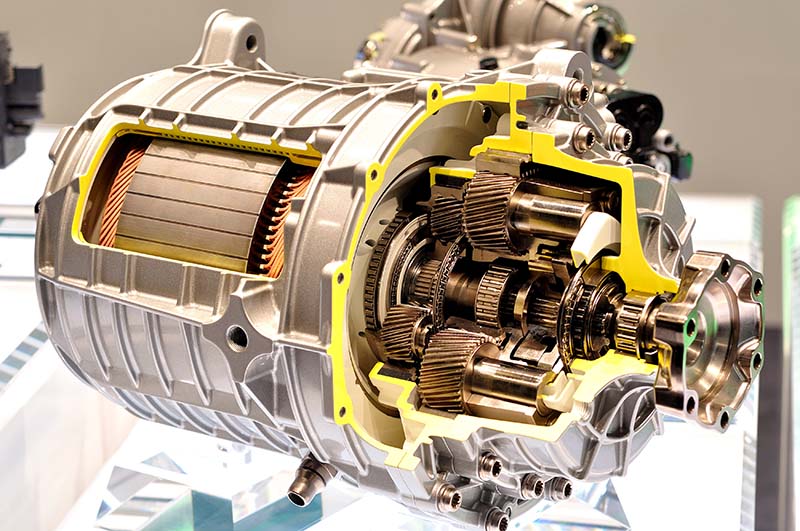

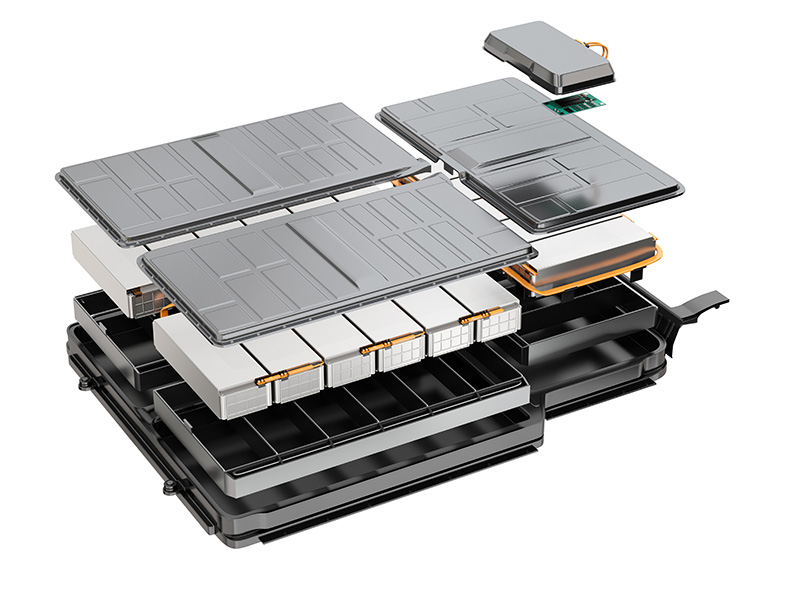

- First and foremost is the move toward hybrid electric drive systems and away from diesel engines. The technological road map will move to a fuel cell hybrid engine and, ultimately, an all-electric drivetrain. This is being done to save significant fuel and shipping costs and to gain an advantage in the field by getting rid of the noisy diesel engines – lessons learned by the U.S. and its allies. Additionally, these new drive systems will need to use fast charger technology to rapidly top up their batteries in dangerous situations.

- Secondly, these new vehicles will be loaded with new hybrid electric technologies – such as integrated starter controllers, power converters, and energy storage technology – that will require an improved power supply.

- Finally, the new vehicles will be packed with new combat systems, such as ruggedized computers, high-speed networks, laser and energy weapons, and high-power jamming systems to name a few. For example, AI-Assisted Detection and Target Recognition (AIDTR) will enable RCVs to rapidly develop a picture of the battlefield by using AI to detect and recognize threats faster and more efficiently than a human. New technology, like AIDTR , will require enough power to far exceed the current 24 volt DC systems.

Amphenol Power Connector Solutions

The challenge is to offer the right power connector solutions to accommodate these new technologies into vehicles that aren’t getting any bigger, while maintaining safety and reliability. For example, in areas where platforms need to downsize connectors without losing current carrying capability, we can offer RADSOK ® or Temper-Grip High Current Contacts to be used in the smaller connectors. Some platforms are adding additional power boxes in tight spaces and severely restricting cable bends, but we have right-angle rigid or flexible busbars that can solve the cable bend problem.

We can even connect these directly to the connector by simply changing the contact termination style from crimp to busbar. In addition, we have product solutions available outside the AMAO group that can help our customers. Amphenol IPC offers a wide array of busbar products and PowerLug wires which can help solve the newest vehicle power technology developments.

The evolution of powertrains from diesel engines to hybrid electric drives to, eventually, fully electric drives, presents new challenges moving forward. An all-electric vehicle will require power connectors that are reliable in the harshest of environments while performing at the maximum voltage and current condition. Amphenol is answering that challenge with the High Power D38999 and the revolutionary Voltarius connector, which can be used in eVTOL applications in addition to the military market.

But Amphenol is uniquely positioned to address these problems because we have the broadest selection of high-power, harsh environment connector solutions in the industry. As the electrification of ground vehicles continue and require new ideas and solutions, we will continue leading the way with our customers. Visit our Electric Mobility Solutions page to learn more about the ways that we're supporting all of these advancements and more.