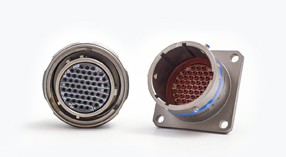

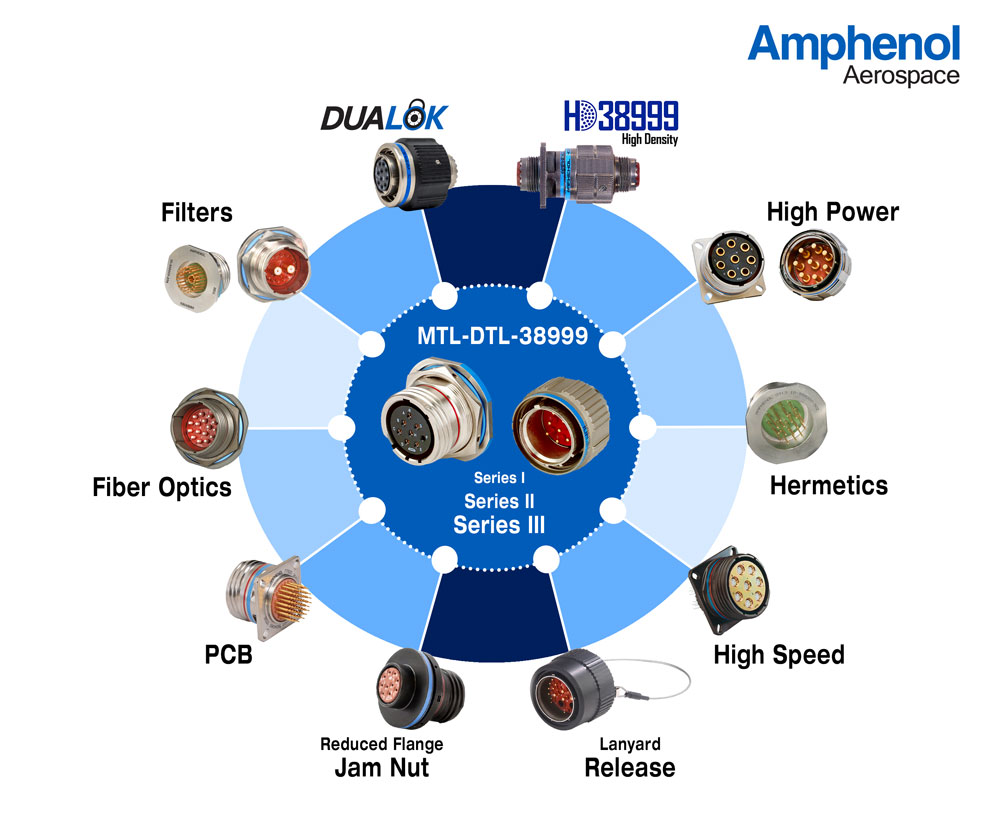

MIL-DTL-38999 Series I, II, and III Connectors, 38999 Derivatives, and Custom Accessories

The Original MIL-SPEC Connectors for Modern Harsh Environments

Amphenol was one of the initial developers of MIL-DTL-38999 when the specification was developed in the 1970s. The Scintilla division of the Bendix Corporation, later incorporated into Amphenol Aerospace, was a key player in the development of MIL-C-38999, which evolved into MIL-DTL-38999 Series I. Bendix also developed the low-profile Bendix JT connectors that became standardized as MIL-DTL-38999 Series II and was instrumental in the development of MIL-DTL-38999 Series III.

The breakthroughs in miniaturization, high-density contact arrangements, and environmental sealing achieved through these connectors became industry-standard features in interconnect technology that are used throughout high-performance military and aerospace applications to this day.

Our MIL-SPEC Qualified Connectors are designed to meet the most rigorous standards for performance and reliability in harsh environments.

- MIL-DTL-38999 Series I, Series II, and Series III

- MIL-DTL-26482 Series II

- MIL-DTL-83723

- MIL-DTL-5015

- MIL-DTL-22992 Class L connectors

With a major role in the development of modern interconnect systems, Amphenol circular MIL-SPEC connectors have been trusted to deliver harsh environment connectivity solutions for mission-critical systems for decades.

Mil-Spec Derivatives

Printed Circuit Board Connectors

High Speed

EMI/EMP Filter Protection

Hermetic/Sealed

Lanyard Release / Quick Disconnect Connectors

Custom Designs and Accessories

MIL-SPEC Connector Derivatives

Options |

|

|---|---|

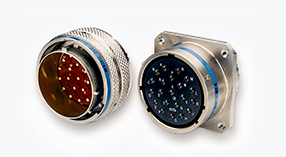

EMI Filter Connectors |

Our Filter Connectors are optimized for electromagnetic interference (EMI) shielding and radio frequency interference (RFI) shielding and are based on the most popular MIL-SPECs: D38999 Series I, II, III; 26482; 5015; and 2M Micro 38999. We also build Filter Adapters for retrofitting existing systems with EMI/RFI shielding, as well as Transient Voltage Suppression (TVS) Diode Connectors and Metal Oxide Varistor (MOV) Connectors for protection against EMP and transient voltage events |

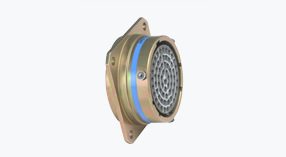

Hermetic Connectors |

Our Hermetic and Sealed Connectors are available in the same MIL-SPECs, with numerous QPL versions. Amphenol hermetically sealed connectors feature glass or epoxy seals, offering superior leak-rate performance in a ruggedized package.

Both Filter, Hermetic, and Sealed Connectors come with various customization options, including special shell geometries, printed circuit board (PCB) contacts, and high-speed contacts. |

Miniature and Micro-Miniature Connectors |

Our collection of Miniature and Micro-Miniature Circular Connectors includes the 2M Micro 38999 series, which delivers the performance of a D38999 Series III connector but in a more compact and lighter form. We also offer the Bantam Micro-Bayonet Series, an economical and lightweight option for general-purpose use in commercial aerospace. Our miniature and micro-miniature solutions also include the Multi-Media Ruggedized (MRC) connectors and the Warrior Grip Series, which is specifically designed for soldier-worn systems, including the U.S. Army's Nett Warrior system. |

High Power Options |

Amphenol’s High Power and High Voltage Connectors and Contacts are capable of handling higher currents and voltages for applications that demand extensive power distribution. |

Waterproof Connectors |

Our Aquacon High Pressure Immersible Connectors are thoroughly sealed against water ingress and incorporate 316 stainless steel shells for corrosion resistance. With the ability to withstand 1500 PSI, Aquacon provides a secure waterproof connection for applications facing extensive fluid immersion or hazardous deep ocean environments. Also available in a hermetic option for an airtight seal that provides extra protection. |

Quick Disconnect Connectors |

Our D38999 Breakaway Fail-Safe Connectors feature a highly durable, lightweight non-metallic lanyard designed to enable rapid quick disconnection. Many other Amphenol connectors such as our 2M Micro-Miniature Series and Push-Pull Connectors incorporate quick disconnect features. |

Dualok High-Vibration Connectors |

Our Dualok High Vibration Connectors are enhanced for severe high-vibration environments and exceed MIL-DTL-38999 Series III vibration resistance. |

Bulkhead Feedthrough Connectors |

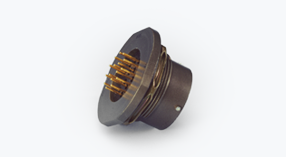

Our bulkhead feedthrough connectors simplify installations by eliminating discrete wire termination and achieving a secure and reliable power or signal connection through a bulkhead or panel. Also available in a fiber-optic connector configuration. |

Jam Nut Connectors |

Our Jam Nut connectors allow you to save space and weight in your PCB applications due to a reduced flange design, which has a smaller profile than standard jam nut receptacles. |

Extensive Contact Options |

Our MIL-SPEC connectors utilize our complete line of crimp, solder, printed circuit tail (PC tail), printed circuit board (PCB), and compliant pin contacts from size 0 to size 22D. |

Connector Savers |

Protect your connectors from the wear and tear of repeated mating and extend their service life with our 38999 Connector Savers. |

RoHS-Compliant Plating |

Environmentally friendly, cadmium-free plating finishes that meet ROHS compliance include gold, electroless nickel, stainless steel, black zinc nickel, our new AP-93 plating, and more. |

Accessories and Custom Options |

We carry a large selection of Accessories and Custom Options for our entire catalog of circular connectors including 38999 integral accessory features, backshells, strain reliefs, caps, and dummy receptacles. |

38999 Plus Offers Endless Options

Amphenol doesn’t just offer connectors within standard MIL-SPEC boundaries; customization beyond MIL-SPEC standards to craft any interconnect solution to meet your unique needs is available through our 38999 Plus catalog. Whether it’s power connectors, signal connectors, or high-speed connectors, 38999 Plus presents a massive inventory of MIL-SPEC styles and options to overcome any interconnect challenges.

Applications

- Military Aircraft

- Commercial Aircraft

- Naval Surface Ships

- Submarines

- Ground Vehicles

- Missile Systems

- Unmanned Vehicles

- Electric Military Vehicles

- Satellites

- Spacecraft

- Avionics Systems

- In-Flight Entertainment Systems

- Landing Systems

- Environmental Control Systems

- Fuel Management Systems

- Refueling Systems

- Power Distribution Systems

- Aircraft Braking Systems

- Communication Systems

- Cabin and Exterior Lighting

- Battery Management Systems