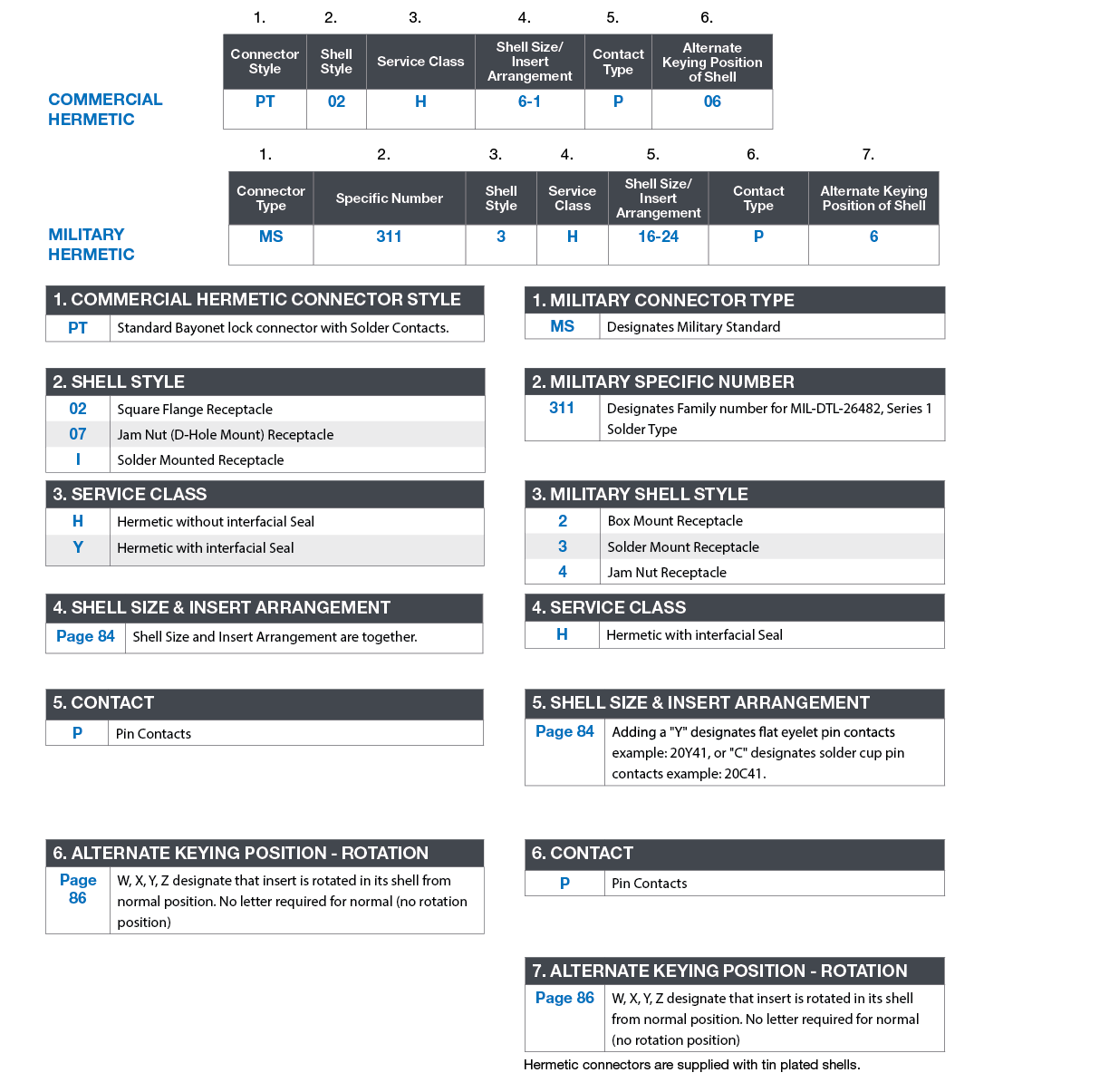

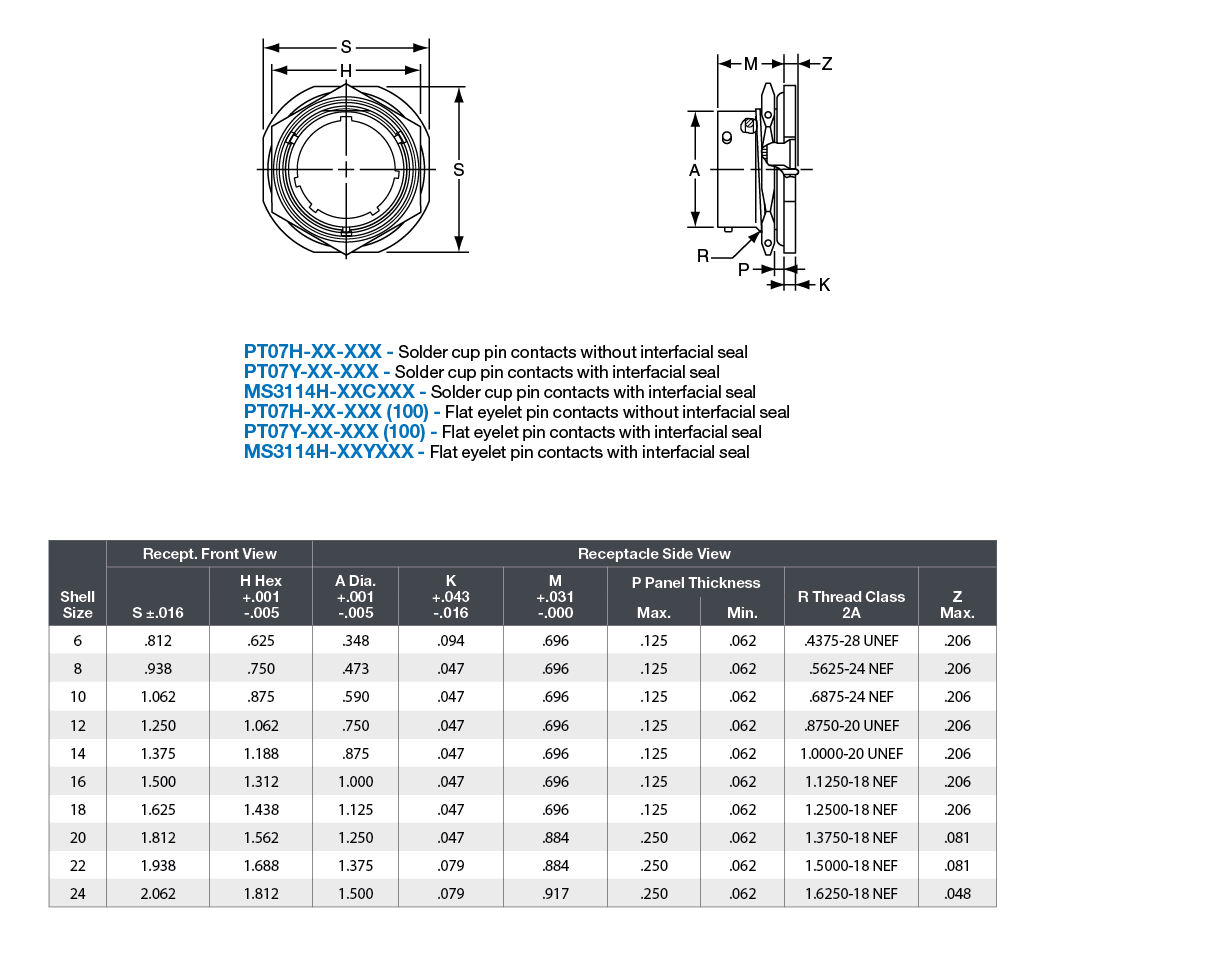

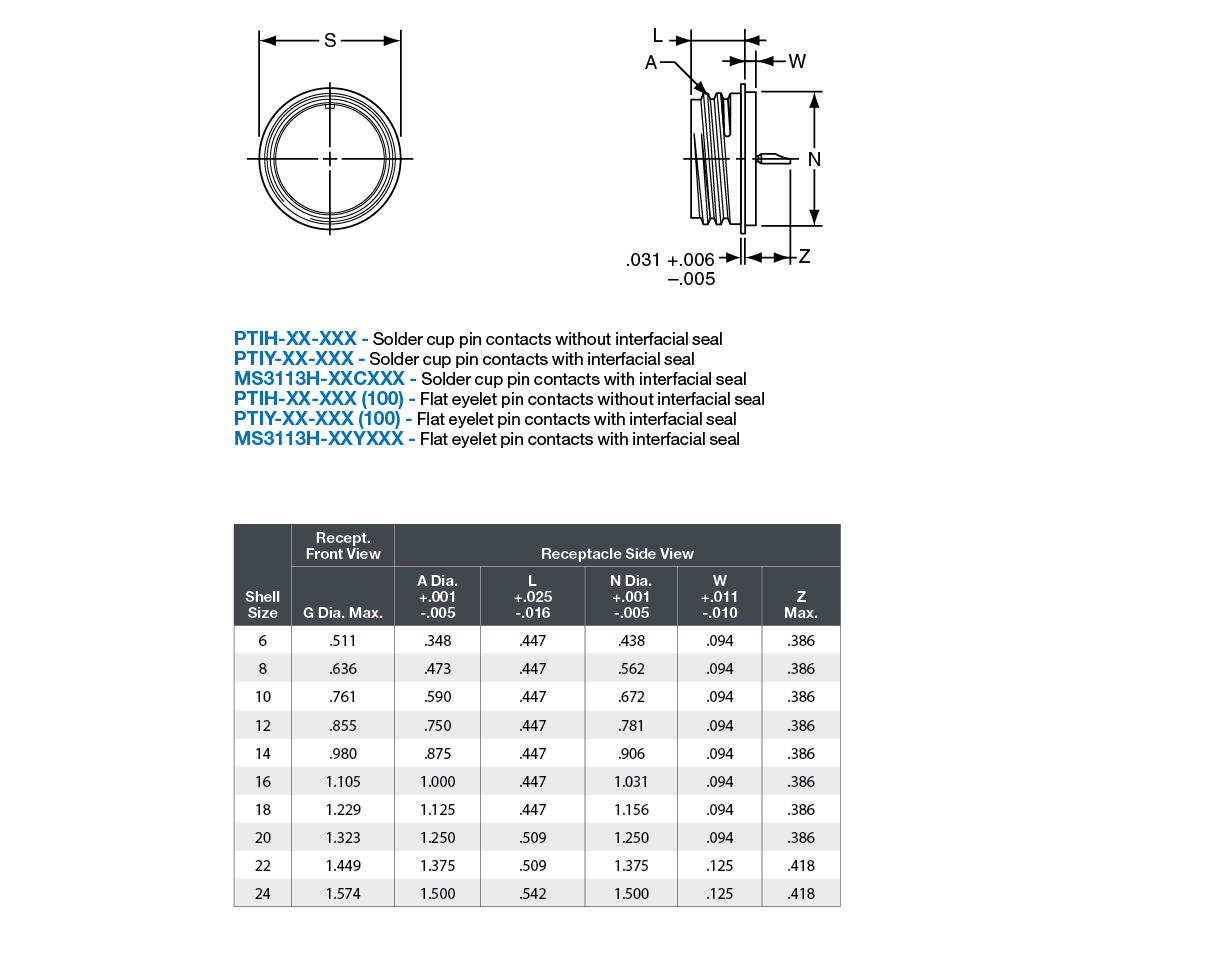

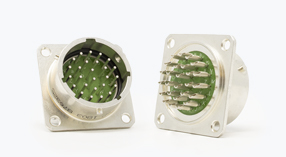

MIL-DTL-26482 Series I Hermetic

Contact:

Description:

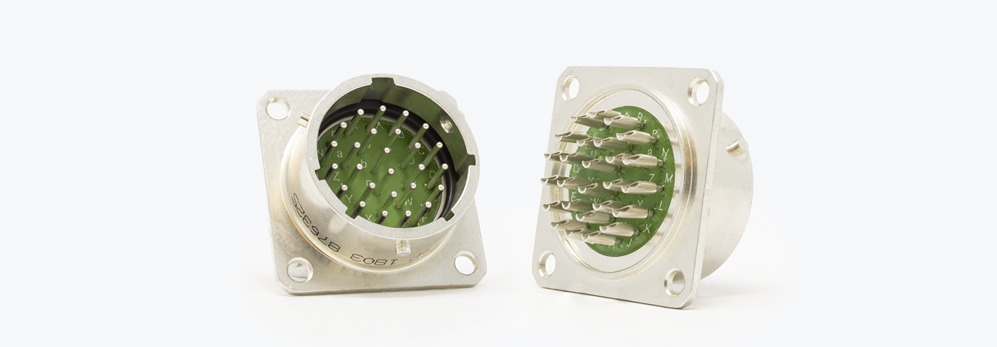

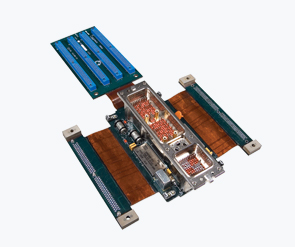

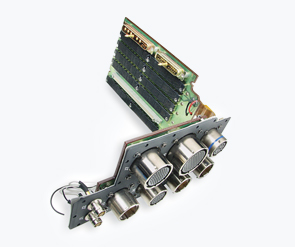

Amphenol MIL-DTL-26482 Hermetic connectors provide twice as many contacts as standard connectors in a small and compact package and feature an airtight glass-to-metal seal for extreme military and commercial aerospace environments.

Coming in at half the size of a standard connector, the 26842 Hermetic features quick-disconnect bayonet coupling for rapid mating and unmating. These connectors come in several shell sizes, contact sizes, and mounting styles, and can operate in a temperature range of -67 °F (-55 °C) to 257 °F (125 °C).

The 26842 Hermetic features an operating voltage of 1,000 VAC (RMS) at sea level.

Features & Benefits:

- Hermetic sealing rated at 1x10-7 cc/sec helium.

- Rugged stainless steel used extensively in military, commercial and aerospace environments

- Operating temperature from -67 °F (-55 °C) to 257 °F (125 °C)

- Operating voltage to 1000 VAC (RMS) at sea level.

- Medium size, environmentally resistant connector

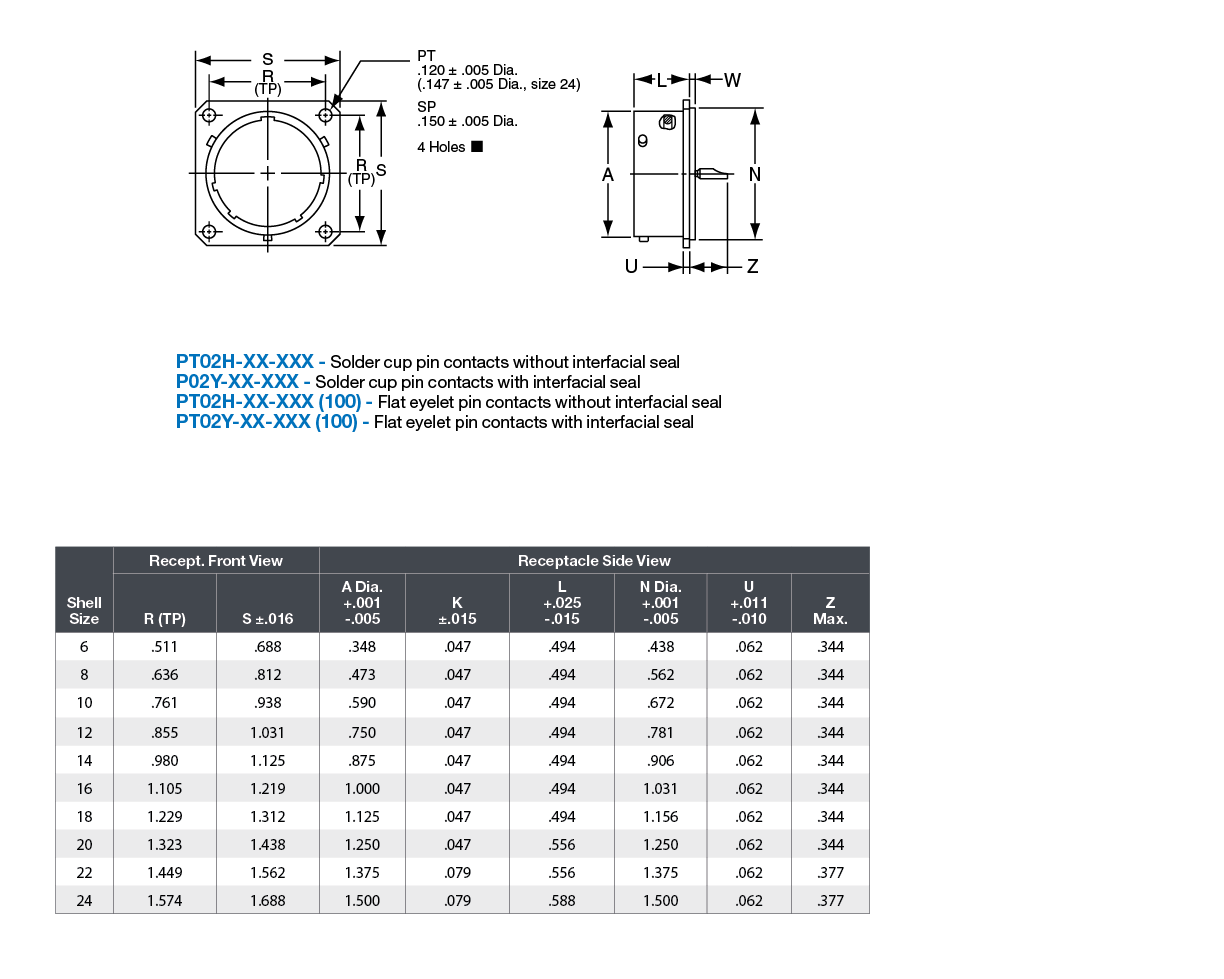

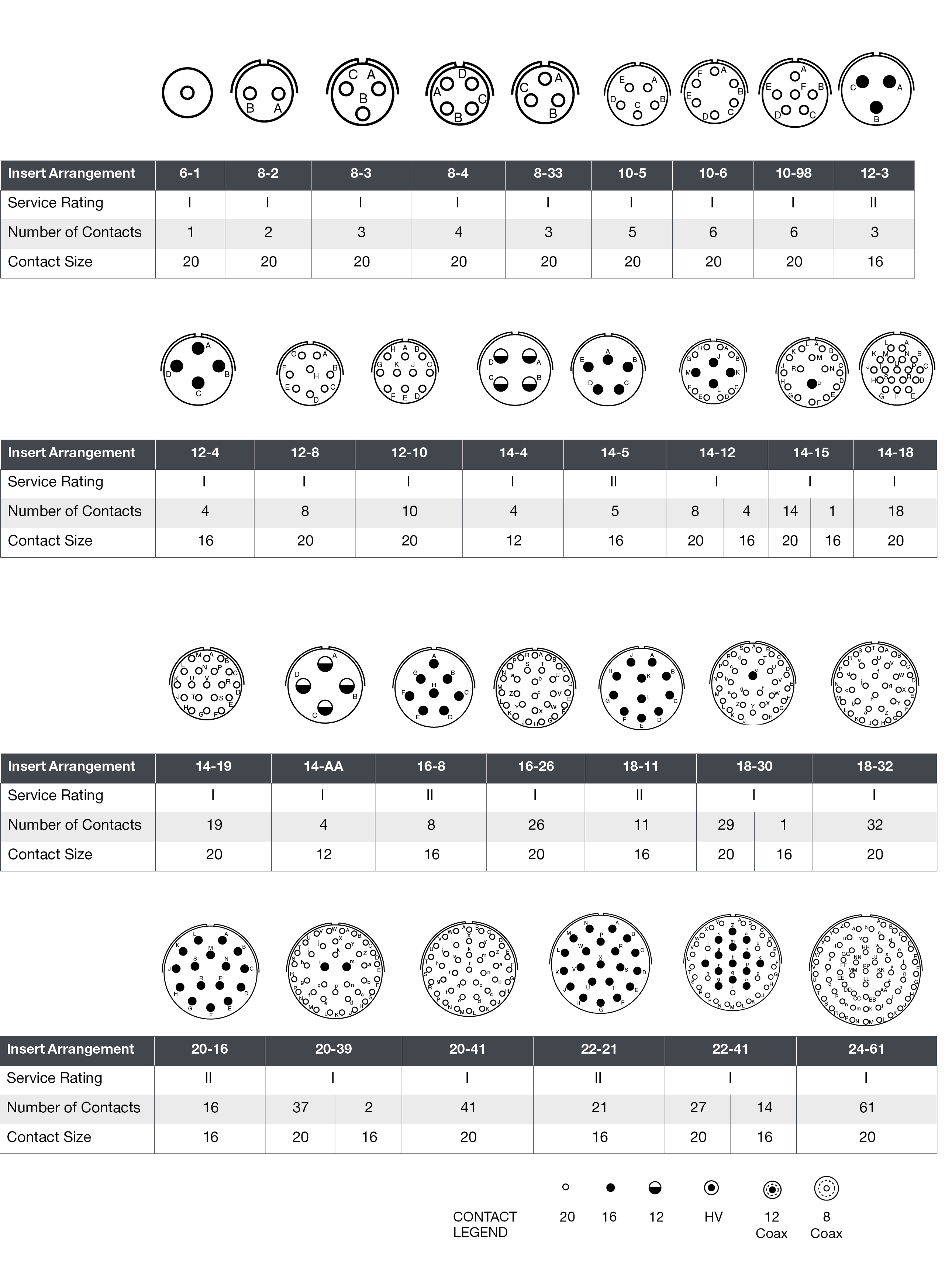

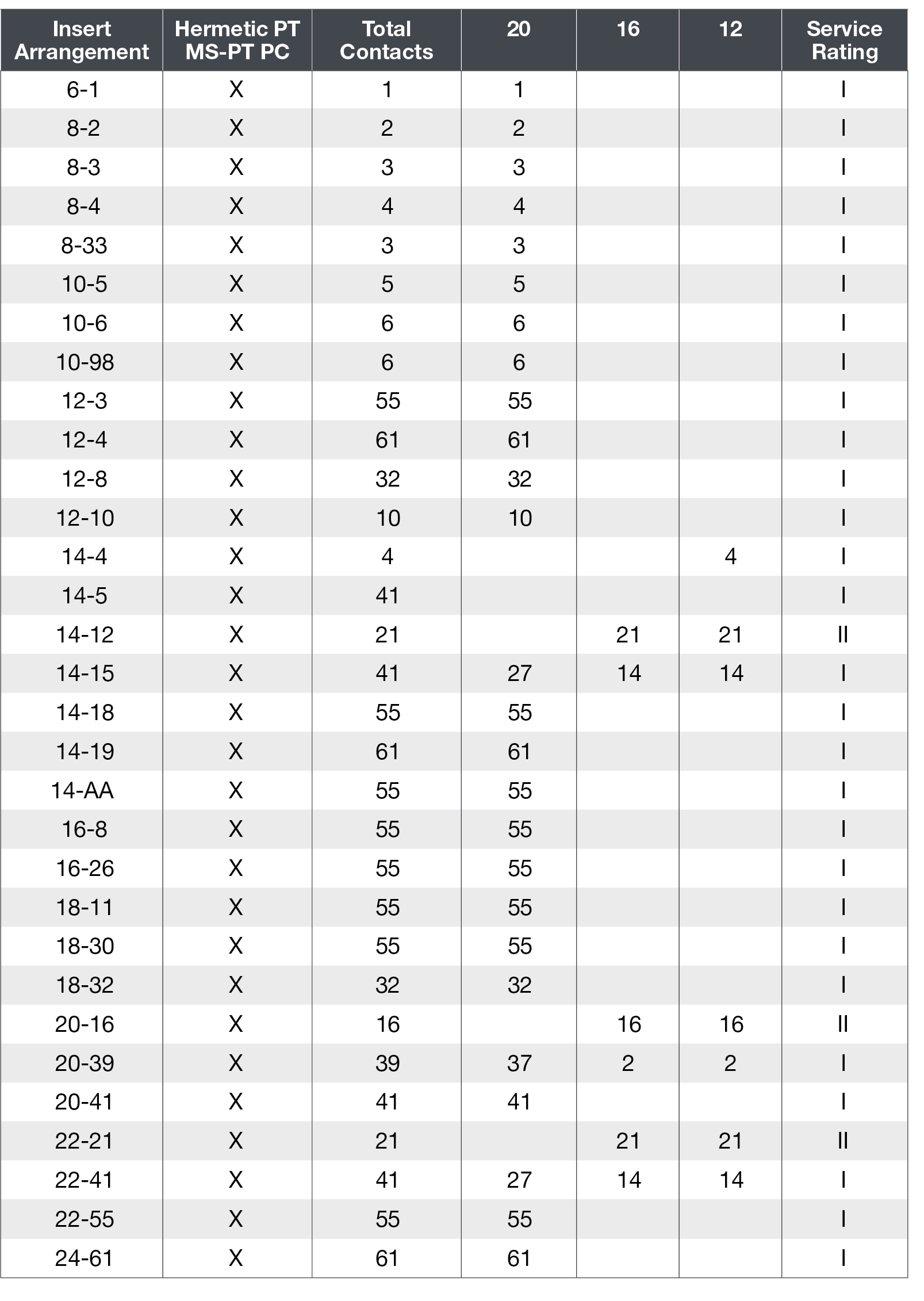

- Shells size 8 to 24. Contact sizes 20, 16, and 12.

- Quick positive coupling assured by a 3-point bayonet coupling system

- Eliminates mismating by the use of five key/keyway design

- 34 insert patterns available from 3 to 55 circuits

- How many Contacts?

Consider including a number of redundant contacts to accommodate any system developments you have planned for the future, or to comply with specified growth provisions. - What are the electrical requirements?

Work out a steady state and peak requirement for both the current and voltage. - Will your Glass-to-Metal Sealing be under any pressure?

Depending on the medium (for example, oil, water, or a vacuum) there may be a pressure differential to consider. Glass-to-Metal Sealing (GTMS) can be supplied in multi-pin preforms or, for high pressure applications in individual glass beads. - How will your GTMS be attached?

Will it be secured with a standard O-ring, for example, or welded in place? - What are your cable interface requirements?

Be sure to include any instructions for screen termination, potting requirements, and/or cable strain relief. - Do you require custom functionality?

If you have any specific requirements, such as electromagnetic compatibility (EMC) filters or printed circuit board (PCB) mounting, make sure they are included in your design specification. - What are your plating requirements?

We offer a wide range of in-house plating options, including tin, nickel, and hard and soft gold. We can also customize the plating to meet any special requirements. Note that gold-plated solder contacts should either be desoldered before installation or appropriate plating thickness specified, to avoid solder embrittlement. - Are there any environmental factors?

If your application will be operating in a harsh or hostile environment (exposed to shock, vibration, thermal changes or extreme temperatures, for example) these will need to be factored into the design. - What are the qualification requirements?

If qualification tests are required, these should be discussed and specified during the design phase. We are able to perform most qualification tests on the appropriate levels of assembly. - What testing will you need?

Examples include leak testing, pressure testing, and geometrical and electrical testing; including breakdown, voltage, and insulation resistance of finished parts. - Cabling and wiring too?

If you would like to extend your brief to include your cabling and wiring requirements, we can address those as well.

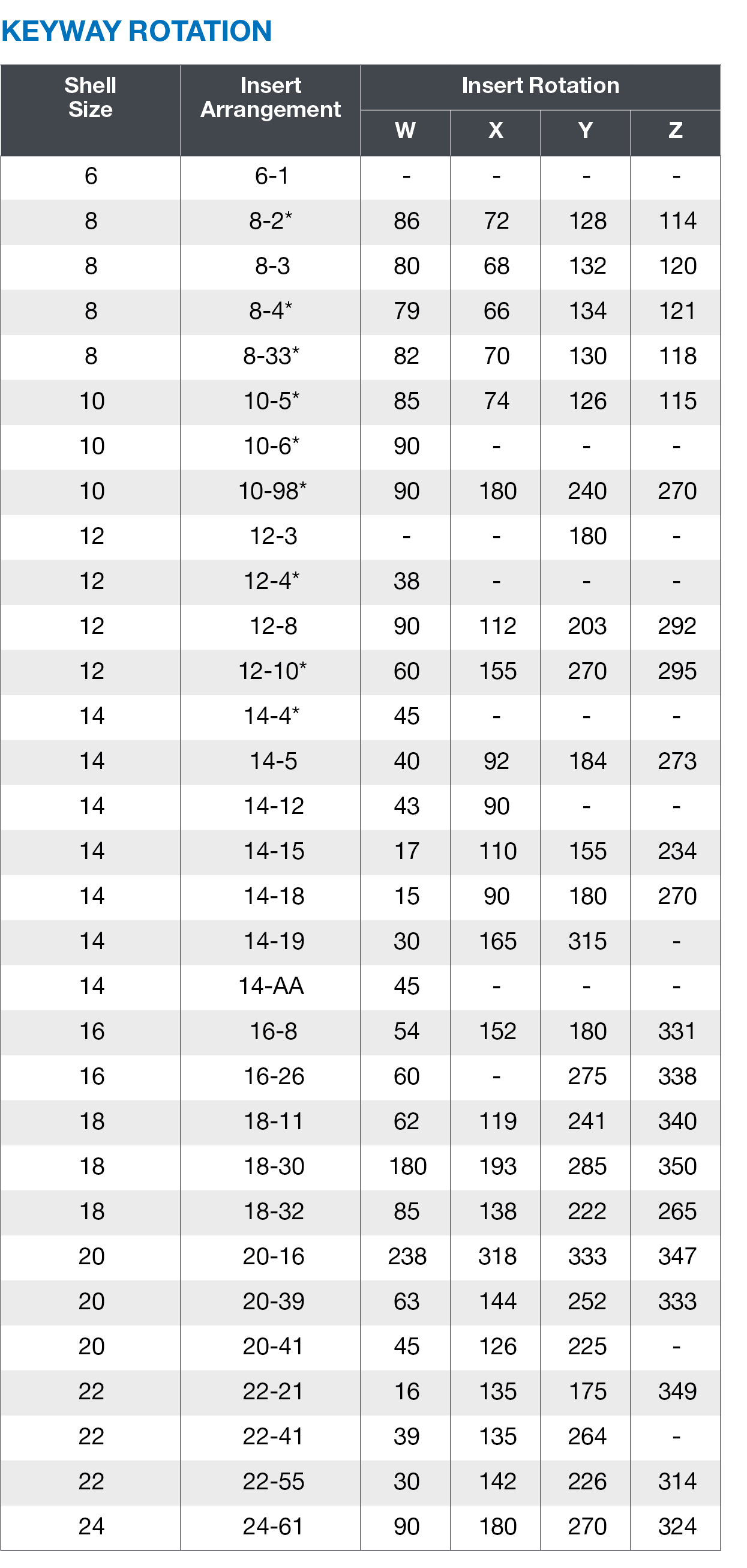

To avoid cross-plugging problems in applications requiring the use of more than one miniature circular connector of the same size and arrangement, alternate insert rotations are available as indicated in the accompanying chart. As shown in the diagram, the front face of the pin insert is rotated within the shell in a clockwise direction from the normal shell key. The socket insert would be rotated counterclockwise the same number of degrees with respect to the normal shell key.