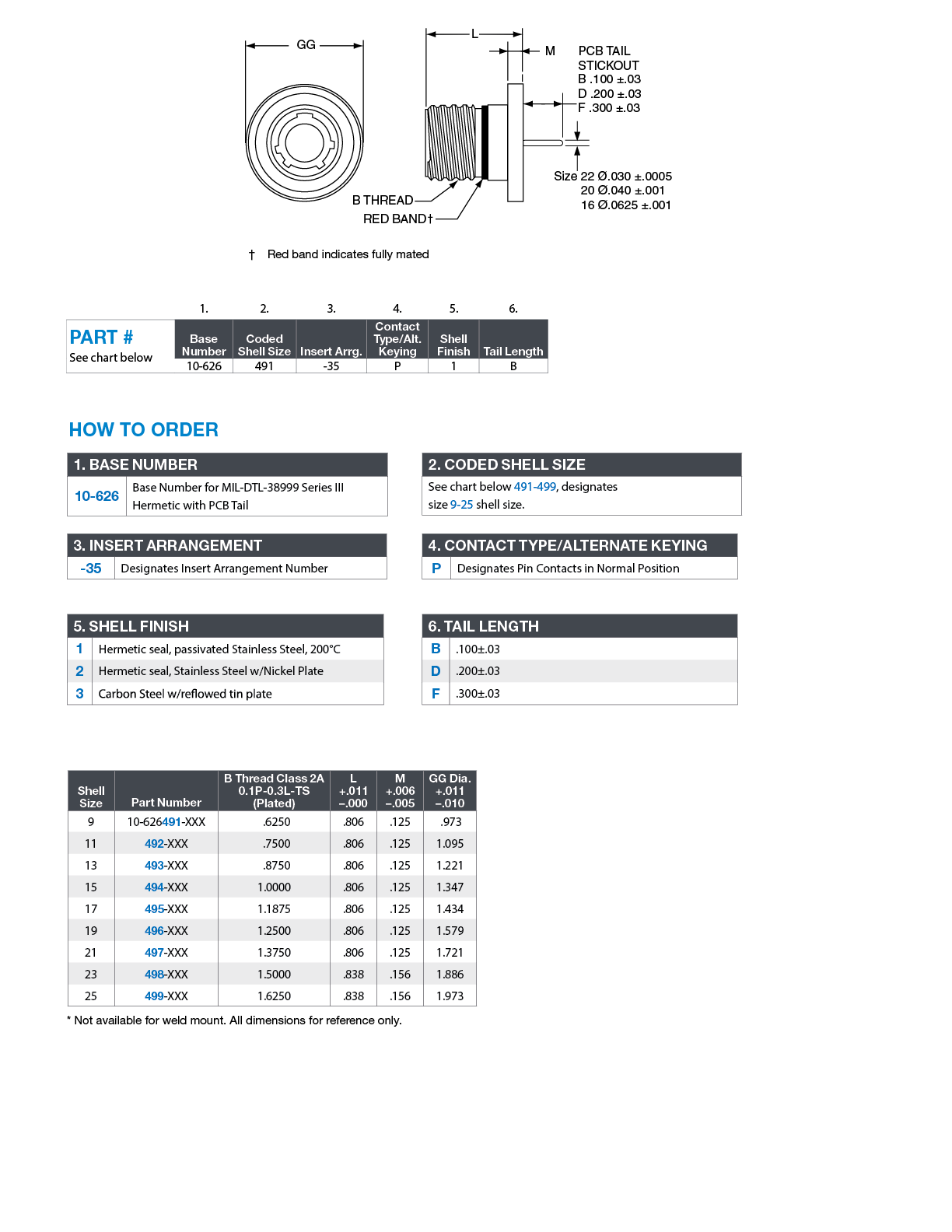

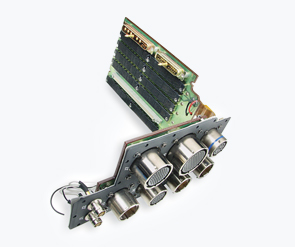

D38999 Series III Hermetic Connectors

Contact:

Description:

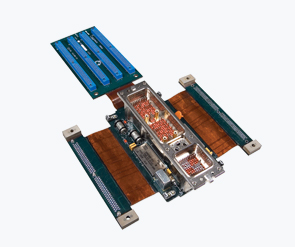

Amphenol Tri-Start MIL-DTL-38999 Series III Hermetic Connectors offer the highest performance capabilities for both general duty and severe environment applications and meet or exceed MIL-DTL-38999 Series III requirements. Amphenol Tri-Start MIL-DTL-38999 Series III Hermetic Connectors offer the performance and design benefits of our standard Tri-Start MIL-DTL-38999 Series III with the addition of a reliable glass to metal seal.

Originally designed for the harshest environments and most demanding applications, Amphenol MIL-DTL-38999 Series III Tri-Start connectors continue to evolve with the needs of an ever-changing market.

Features & Benefits:

- Hermetic- air leakage tested to 1x10-7 cc/sec helium

- EMI Shielding: Solid metal-to-metal coupling, grounding fingers, electroless nickel plating, and thicker wall sections provide superior EMI shielding capability of 65dB minimum at 10 GHz

- Contact Protection: Recessed pins in this 100% scoop-proof connector minimize potential contact damage

- Moisture Resistance: Improved interfacial seal design helps prevent electrolytic erosion of contacts

- Corrosion Resistance: Shells of stainless steel with nickel plating withstand a 500-hour salt spray exposure

- Vibration/Shock: Operates under severe high-temperature vibration, through 200°C

- Lockwiring Eliminated: Unique, self-locking, quick coupling connector eliminates lockwiring

- Quick Coupling: Completely mates and self-locks in a 360° turn of the coupling nut

- How many Contacts?

Consider including a number of redundant contacts to accommodate any system developments you have planned for the future, or to comply with specified growth provisions. - What are the electrical requirements?

Work out a steady state and peak requirement for both the current and voltage. - Will your Glass-to-Metal Sealing be under any pressure?

Depending on the medium (for example, oil, water, or a vacuum) there may be a pressure differential to consider. Glass-to-Metal Sealing (GTMS) can be supplied in multi-pin preforms or, for high pressure applications in individual glass beads. - How will your GTMS be attached?

Will it be secured with a standard O-ring, for example, or welded in place? - What are your cable interface requirements?

Be sure to include any instructions for screen termination, potting requirements, and/or cable strain relief. - Do you require custom functionality?

If you have any specific requirements, such as electromagnetic compatibility (EMC) filters or printed circuit board (PCB) mounting, make sure they are included in your design specification. - What are your plating requirements?

We offer a wide range of in-house plating options, including tin, nickel, and hard and soft gold. We can also customize the plating to meet any special requirements. Note that gold-plated solder contacts should either be desoldered before installation or appropriate plating thickness specified, to avoid solder embrittlement. - Are there any environmental factors?

If your application will be operating in a harsh or hostile environment (exposed to shock, vibration, thermal changes or extreme temperatures, for example) these will need to be factored into the design. - What are the qualification requirements?

If qualification tests are required, these should be discussed and specified during the design phase. We are able to perform most qualification tests on the appropriate levels of assembly. - What testing will you need?

Examples include leak testing, pressure testing, and geometrical and electrical testing; including breakdown, voltage, and insulation resistance of finished parts. - Cabling and wiring too?

If you would like to extend your brief to include your cabling and wiring requirements, we can address those as well.

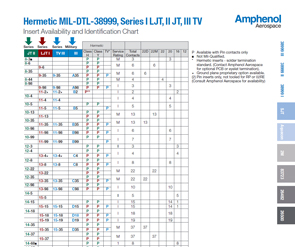

SERVICE RATING*

| Service Rating | Suggested Operating Voltage (Sea Level) |

Test Voltage | ||||

| AC (RMS) | DC | Sea Level | 50,000 ft. | 70,000 ft. | 110,000 ft. | |

| M | 400 | 500 | 1300 VRMS | 550 VRMS | 350 VRMS | 200 VRMS |

| N | 300 | 450 | 1000 VRMS | 400 VRMS | 260 VRMS | 200 VRMS |

| I | 600 | 850 | 1800 VRMS | 600 VRMS | 400 VRMS | 200 VRMS |

| II | 900 | 1250 | 2300 VRMS | 800 VRMS | 500 VRMS | 200 VRMS |

** Please note that the establishment of electrical safety factors is left entirely in the designer’s hands since they are in the best position to know

what peak voltage, switching surges, transients, etc. can be expected in a particular circuit.

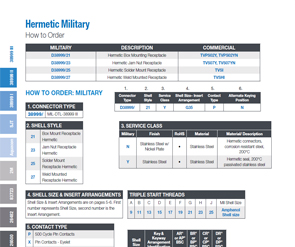

| Hermetic Shell Components | ||

| Material/Finish | Service Class | |

| Military | Commercial | |

| Stainless Steel | Y | Y |

| Stainless Steel with Nickel Plate | N | YN |

| Hermetic Connectors | ||||

| Finish | Suffix | Indicated Finish Standard for JT Types Listed Below | Indicated Finish Standard for LJT Types Listed Below | |

| Military | Commercial | |||

| Carbon Steel Shell Tin Plated Shell and Contacts |

JT( )H / JT( )Y JTL( )H / JTL( )Y |

LJT( )Y LJT( )H |

||

| Carbon Steel Shell Tin Plated Shell and Gold Plated Contacts | MS (D) | |||

| Stainless Steel Shell Gold Plated Contacts | MS (E) | (162) | JTS( )Y JTLS( )Y |

LJTS( )Y |