Login

You must first login to download drawings/models.

Incorrect username or password.

You must first login to download drawings/models or register for webinars.

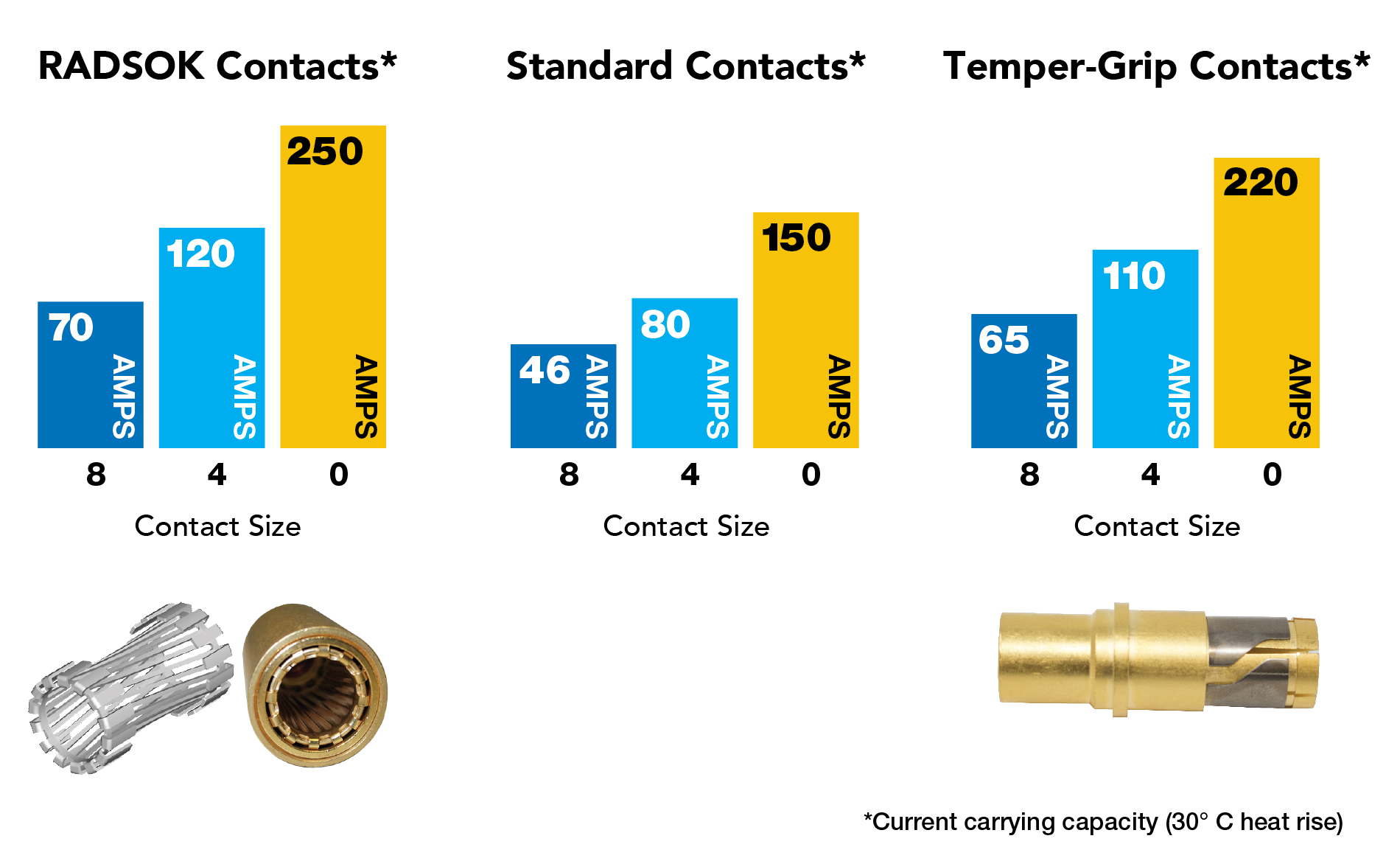

The High Power 5015 Series features advanced socket contact technology that provides a 40-50 percent higher current carrying capacity compared to standard 5015 connector contacts. These high-power connectors feature proven RADSOK® technology along with the high current, high-temperature Temper-Grip to provide a solution for any operating temperature. Utilizing the proven Matrix 5015 and MGT-5015 connector mating designs and a host of new contact termination methods, the High Power series offers custom connector performance in a standard catalog offering.

The High Power 5015 is fully tooled utilizing readily available military-qualified inserts.

Low Contact Engagement/Separation Forces:

The hyperbolic lamella socket contact construction distributes normal forces over a high percentage of mating pin surface. This creates a smooth, even engagement effort. This force distribution also contributes to excellent performance in vibration applications with resistance to typical fretting corrosion.

Low Contact Resistance:

The large interface area between the socket lamella and pin surface results in very low contact resistance, enabling the RADSOK® contacts’ high current rating compared to traditional power contact designs.

High Mating Cycle Durability:

RADSOK contacts with typical silver plating finishes have demonstrated the survival of 20,000 mating cycles. Even with continuous exposure to harsh environmental abuse (salt, sand, and high humidity). RADSOK contacts have been tested to maintain low contact resistance beyond 10,000 mating cycles.

| Standard Contacts | RADSOK Contacts | ||||

| Size | Amps | Size | Amps | Cartridge Size | |

| 8 | 46 | 8 | 70 | 3.6mm | |

| 4 | 80 | 4 | 120 | 5.7mm | |

| 0 | 150 | 0 | 250 | 9.1mm | |

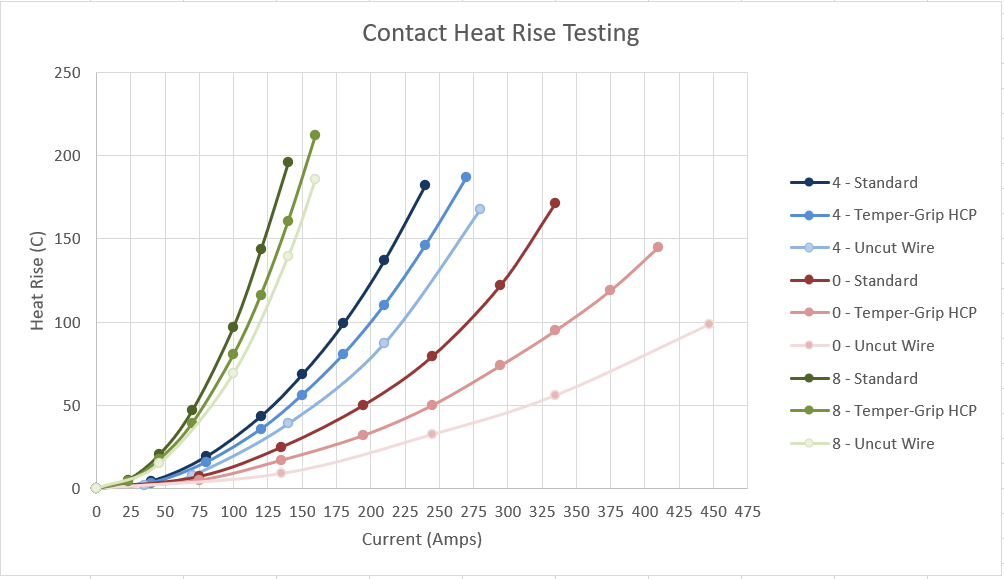

High Temperature Capability:

For use in high temperature (200 C+) applications, the Temper-grip socket has been tested to maintain current capability in high-temperature situations where standard mil-spec socket contacts can begin to relax.

“Napkin-Ring” Technology:

Proven design utilizing a stainless steel napkin ring to prevent the beryllium copper tines from “relaxing” at higher temperatures and maintaining a greater area of true contact in all situations to decrease resistance.

| Standard Contacts | Temper-Grip Contacts | |||

| Size | Amps | Size | Amps | |

| 8 | 46 | 8 | 65 | |

| 4 | 80 | 4 | 110 | |

| 0 | 150 | 0 | 220 | |

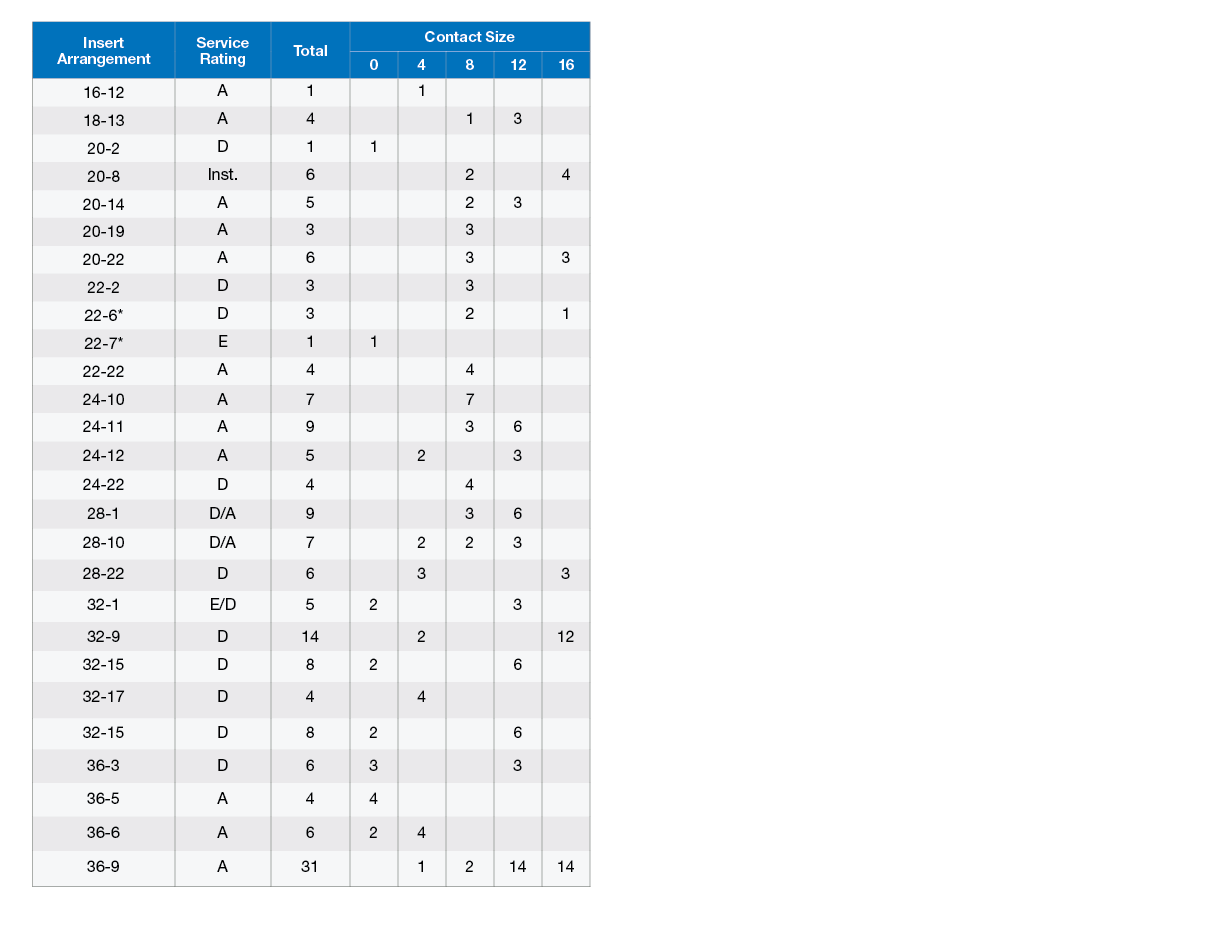

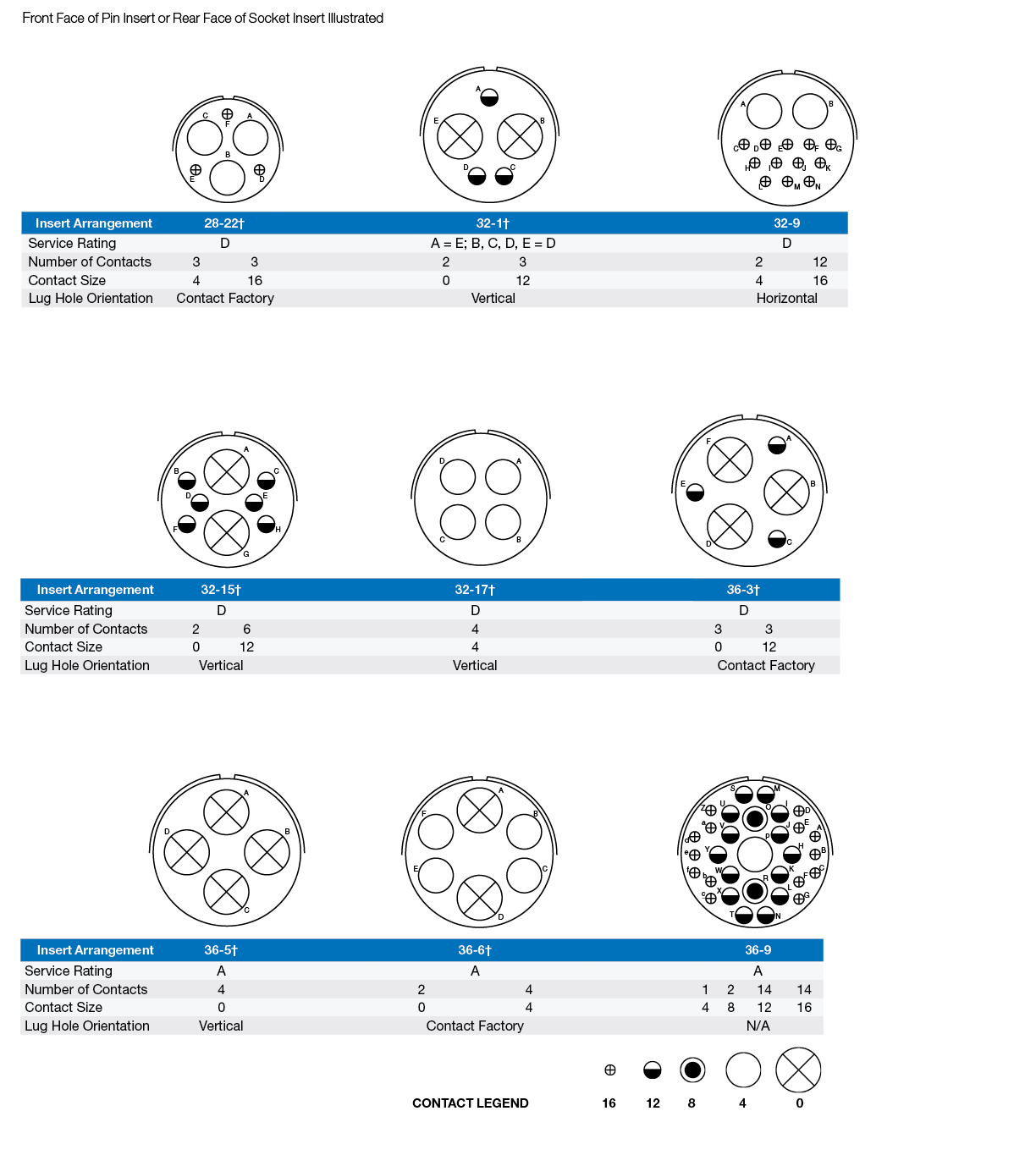

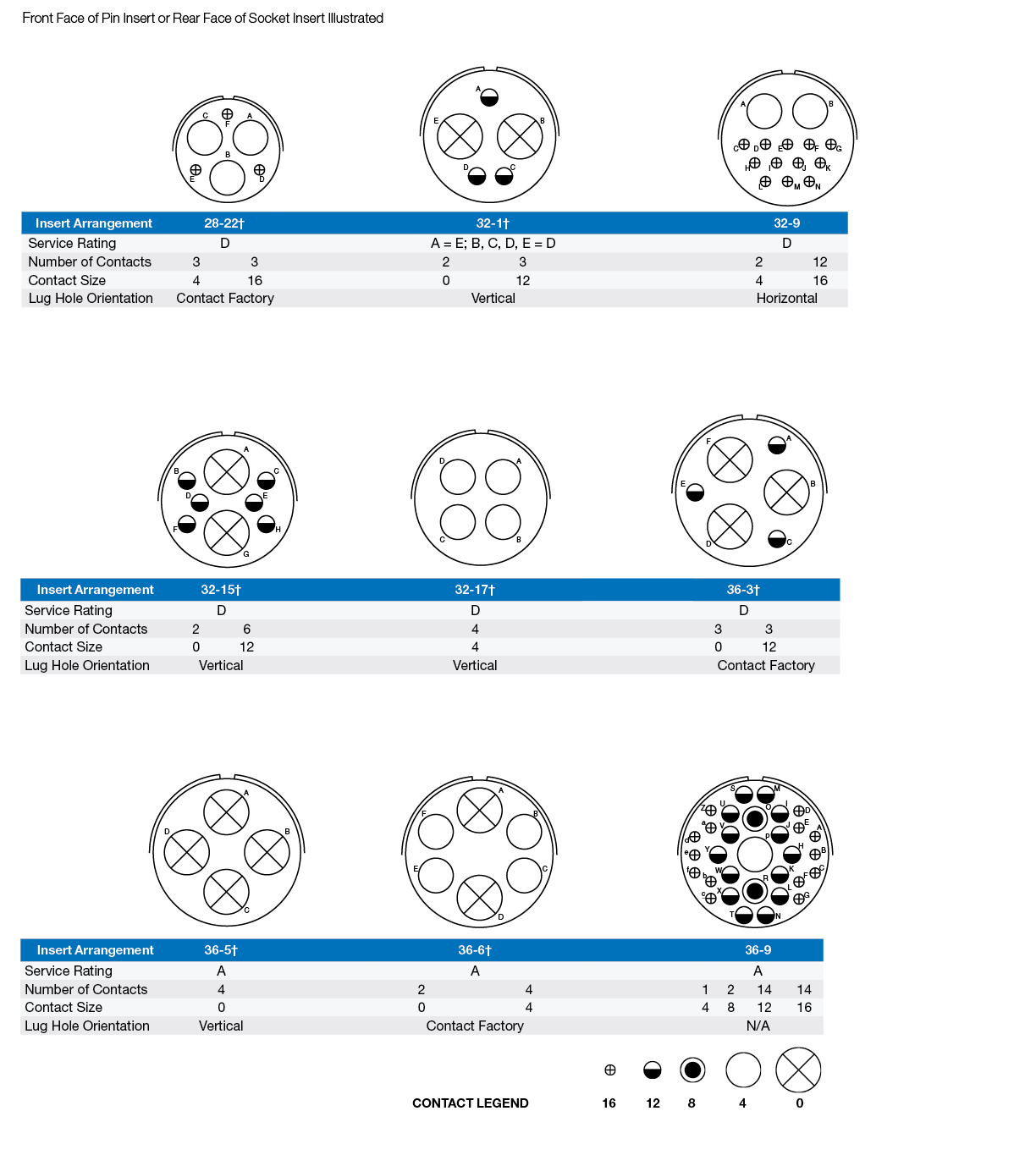

| High Power 5015 | Amperage Performance | Contact Size | Voltage Rating | ||||||||

| Insert Arrangement | Standard Contacts | Temper-Grip | Radsok | 0 | 4 | 8 | 12 | 16 | Total Contacts | Service Rating | Operating Voltage (Sea Level) |

| 16-12 | 80 | 110 | 120 | 1 | 1 | A | 700VDC / 500VAC | ||||

| 18-13 | 115 | 134 | 149 | 1 | 3 | 4 | A | 700VDC / 500VAC | |||

| 20-14 | 161 | 199 | 229 | 2 | 3 | 5 | A | 700VDC / 500VAC | |||

| 20-19 | 138 | 195 | 240 | 3 | 3 | A | 700VDC / 500VAC | ||||

| 20-2 | 150 | 220 | 250 | 1 | 1 | D | 1250VDC / 900VAC | ||||

| 20-22 | 177 | 234 | 279 | 3 | 3 | 6 | A | 700VDC / 500VAC | |||

| 20-8 | 144 | 182 | 212 | 2 | 4 | 6 | Inst. | 250 VDC/ 200VAC | |||

| 22-2 | 138 | 195 | 240 | 3 | 3 | D | 1250VDC / 900VAC | ||||

| 22-21 | 176 | 246 | 276 | 1 | 2 | 3 | A | 700VDC / 500VAC | |||

| 22-22 | 184 | 260 | 320 | 4 | 4 | A | 700VDC / 500VAC | ||||

| 22-6 | 105 | 143 | 173 | 2 | 1 | 7 | D | 1250VDC / 900VAC | |||

| 22-7 | 150 | 220 | 250 | 1 | 1 | E | 1750VDC/1250VAC | ||||

| 24-10 | 322 | 455 | 560 | 7 | 7 | A | 700VDC / 500VAC | ||||

| 24-11 | 276 | 333 | 378 | 3 | 6 | 9 | A | 700VDC / 500VAC | |||

| 24-22 | 184 | 260 | 320 | 4 | 4 | D | 1250VDC / 900VAC | ||||

| 28-1 | 276 | 333 | 378 | 3 | 6 | 9 | D/A | 1250VDC / 900VAC | |||

| 28-10 | 321 | 419 | 469 | 2 | 2 | 3 | 7 | D/A | 1250VDC / 900VAC | ||

| 28-22 | 279 | 369 | 399 | 3 | 3 | 6 | D | 1250VDC / 900VAC | |||

| 32-1 | 369 | 509 | 569 | 2 | 3 | 5 | E/D | 1250VDC / 900VAC | |||

| 32-15 | 438 | 578 | 638 | 2 | 6 | 10 | D | 1250VDC / 900VAC | |||

| 32-17 | 320 | 440 | 480 | 4 | 4 | D | 1250VDC / 900VAC | ||||

| 32-9 | 316 | 376 | 396 | 2 | 12 | 14 | D | 1250VDC / 900VAC | |||

| 36-3 | 519 | 729 | 819 | 3 | 3 | 6 | D | 1250VDC / 900VAC | |||

| 36-5 | 600 | 880 | 1000 | 4 | 22 | A | 700VDC / 500VAC | ||||

| 36-6 | 620 | 880 | 980 | 2 | 4 | 6 | A | 700VDC / 500VAC | |||

| 36-9 | 676 | 744 | 784 | 1 | 2 | 14 | 14 | 31 | A | 700VDC / 500VAC | |

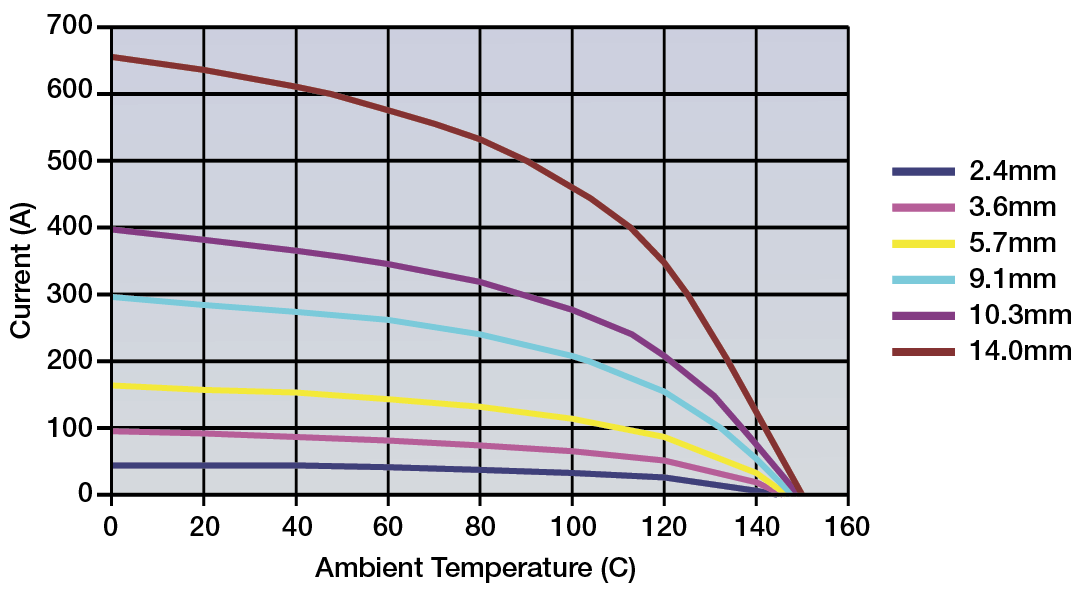

Amperage Performance Chart

| Contact Size | 0 | 4 | 8 | 12 | 16 |

| Standard | 150 | 80 | 46 | 23 | 13 |

| Radsok | 250 | 120 | 80 | 23 | 13 |

| Temper-Grip | 220 | 110 | 65 | 23 | 13 |

| Feature | High Power 38999 | High Power 5015 |

| Threaded Coupling or Reverse Bayonet | X | |

| Main Joint Gasket | X | |

| Molded Insert Design | X | |

| New Plug Shell Design for 10X improved durability in corrosive environments (Patent Penting) | X | |

| Radsok Contacts | ||

| Current Carrying Capabilities up to 250 Amps Per Contact | X | X |

| Gold or Silver Plating Available | X | X |

| Temper-Grip Contacts | ||

| Current Carrying Capability up to 220 Amps per Contact | X | X |

| Temperature Rating of up to 200C+ | X | X |

| Gold or Silver Plating Available | X | X |

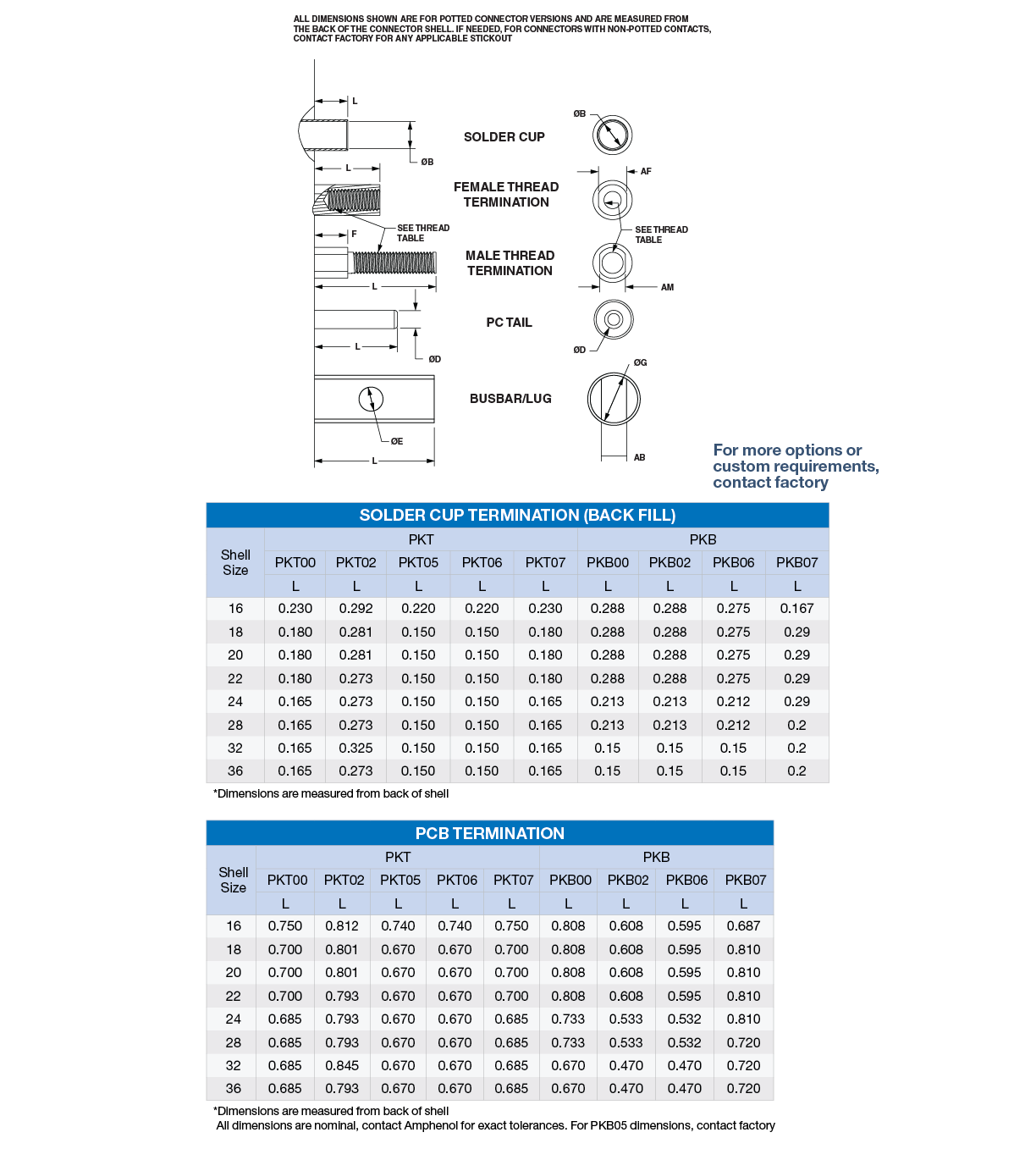

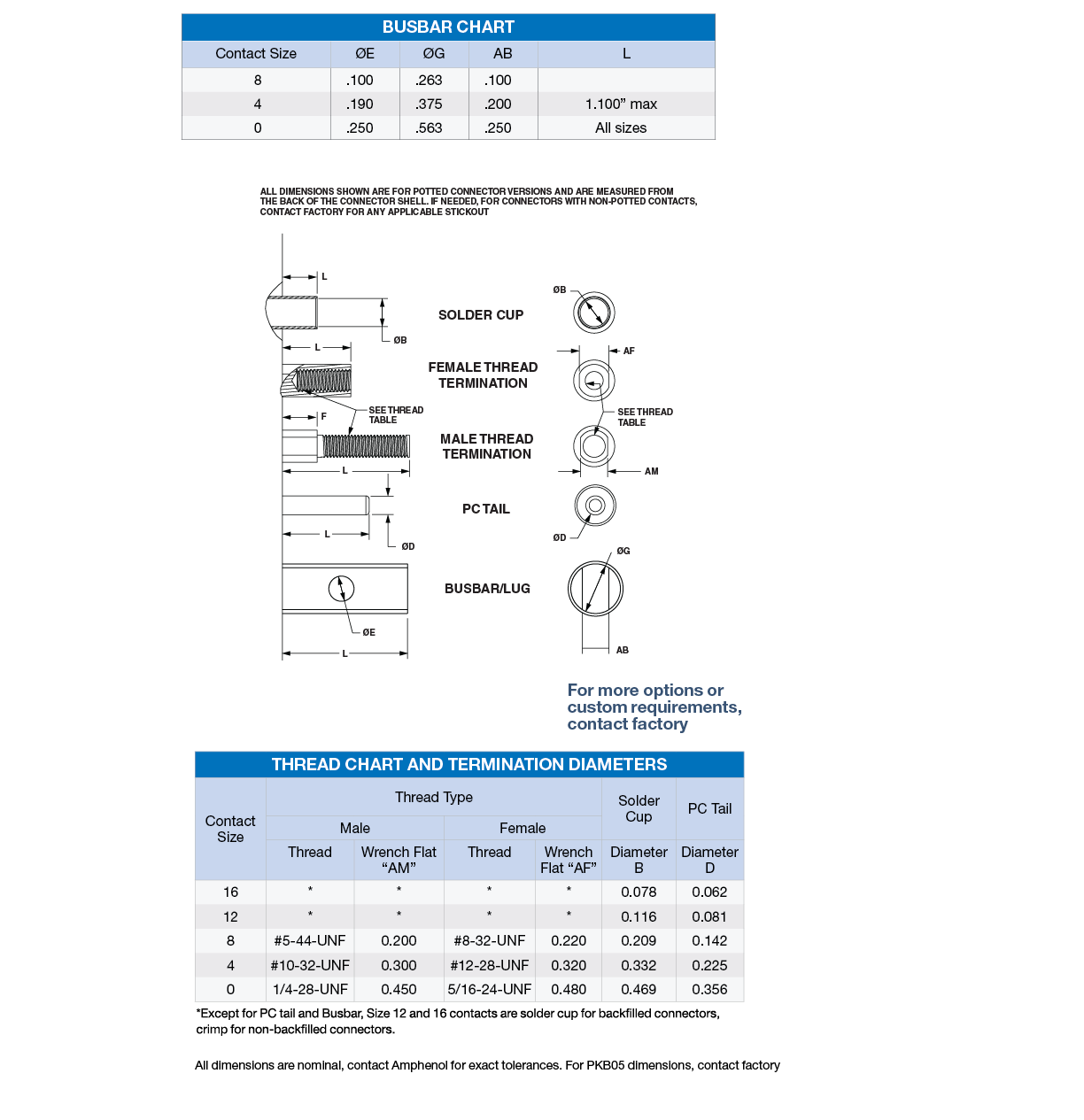

| Termination Methods | ||

| Crimp | X | X |

| Solder Cup | X | X |

| Threaded Post | X | X |

| Busbar Termination | X | X |

| Next Generation Shell Plating Options Available | ||

| 1000 Hour AP-93 |

X | X |

| Sealing | ||

| EMI Band for improved sealing and Db Loss | X | |

| Interfacial Seal "Cork and Bottle Design" | X | X |

| Wiper Seal | X | |

| Front and Rear Grommets for Moisture Sealing | X | |

| Rear Insert for Moisture Sealing | X | |