Circular Connectors - Mil-Spec, Micro-Miniature, Filter, Sealed, and Custom

What are MIL-SPEC connectors?

MIL-SPEC connectors, or Military Specification connectors or MIL-standard connectors, are ruggedized circular electrical connectors designed to meet the demanding connection requirements of military and aerospace applications. These connectors provide unwavering power and signal connectivity in harsh environments for mission-critical systems that cannot fail under any circumstances. Common applications for MIL-SPEC connectors include military ground vehicles, aircraft, naval ships, communications equipment, and other mission-critical systems.

Because they’re intended to operate without failure in the harshest environments, including desert, mountainous, and lush landscapes throughout the world, littoral and deep ocean waters, high altitudes, and space, these connectors are constructed from premium aerospace-grade materials. This includes but isn’t limited to, high-quality metal alloys such as 6061-T6 aluminum, passivated stainless steel, and composite materials to enhance strength and corrosion resistance in the face of high vibrations, moisture, dust, electromagnetic interference, and other environmental threats to system integrity.

Industry Leading Connector Innovation

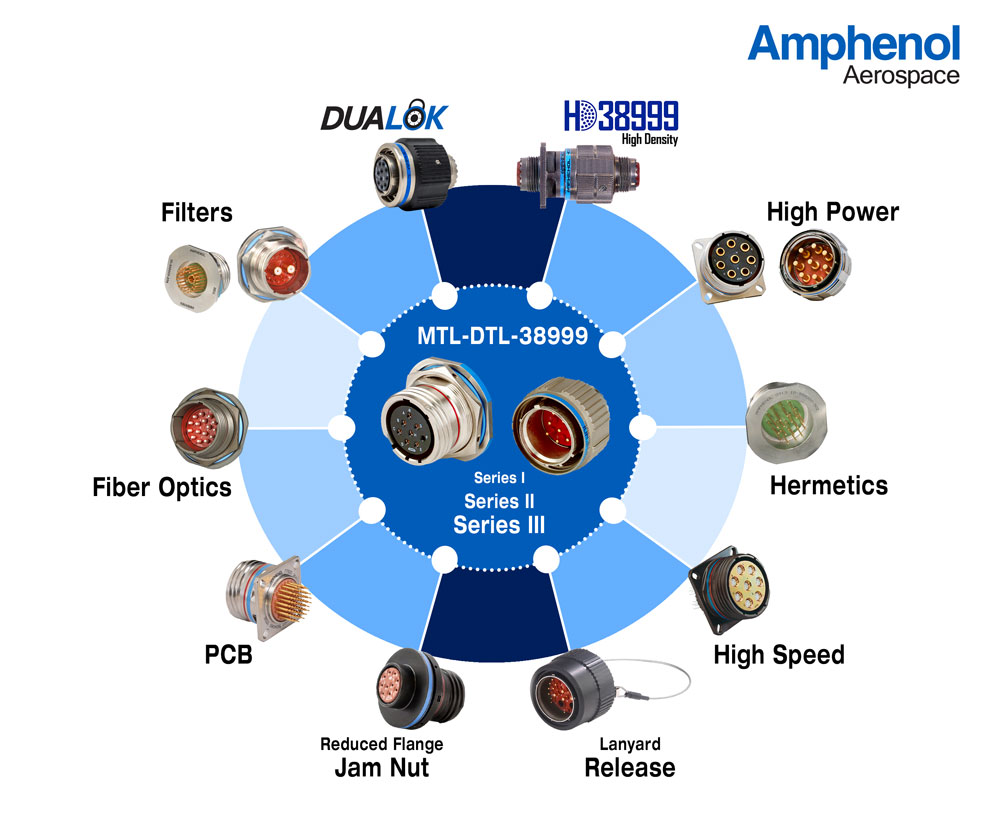

Amphenol Aerospace offers a comprehensive range of MIL-SPEC connectors and MIL-SPEC derivative connectors including micro-miniature connectors, EMI and EMP filter connectors, and hermetic and epoxy-sealed connectors to meet any interconnectivity challenge in harsh environments. Amphenol Aerospace has extensive experience manufacturing MIL-SPEC connectors for the Military and Aerospace markets going back to World War II during the early days of defense standardization. Amphenol circular connectors are also ideal for and widely used in commercial air applications and are trusted by major airlines and manufacturers worldwide.

Choosing the Right Connector

.jpg)

38999 Plus offers a lot of interconnect options within and outside of MIL-SPEC standards. When choosing the right circular connector for your application, there are a couple of factors you should consider.

What Kind of Environment?

The environment where the connector will be used is paramount. Factors such as temperature extremes, exposure to moisture, dust, chemicals, and vibration can all impact connector performance and system integrity. Ensuring the connector has proper sealing, corrosion resistance, and durability against the elements is critical for reliable operation.

What is the Termination Method?

The termination method refers to how the connector is attached to the cable or wire. Common methods include crimping and soldering. Choosing the right termination method will depend on a host of factors, including what kind of application the connector is being used for, ease of installation, time, reliability, and the type of connector itself. Whichever method is chosen, developers must ensure it allows for a secure and efficient connection that meets the application’s requirements.

What Kind of Contacts, and In What Insert Arrangement?

The type, material, and configuration of contacts within the connector are vital for ensuring effective power and signal. Contacts can be made from various materials, including gold and copper, each offering different levels of conductivity and durability. The arrangement and density of the contacts should match the application's needs, whether it’s for high-speed data transfer, power distribution, or signal integrity.

What Type of Design Fits Best with My Application?

The connector’s design, including its size, shape, and coupling mechanism, must align with your application’s physical constraints and requirements. When assessing the right design for your application you should also consider the connector’s ease of use, such as how quickly and securely the connector can be mated and unmated; its degree of ruggedness and ability to withstand harsh environments, and whether it includes features like keying to prevent misalignment.

Types of MIL-SPEC connectors

MIL-SPEC connectors are manufactured per a variety of military specifications. Some of the most popular MIL-SPECs include the following:

MIL-DTL-38999 |

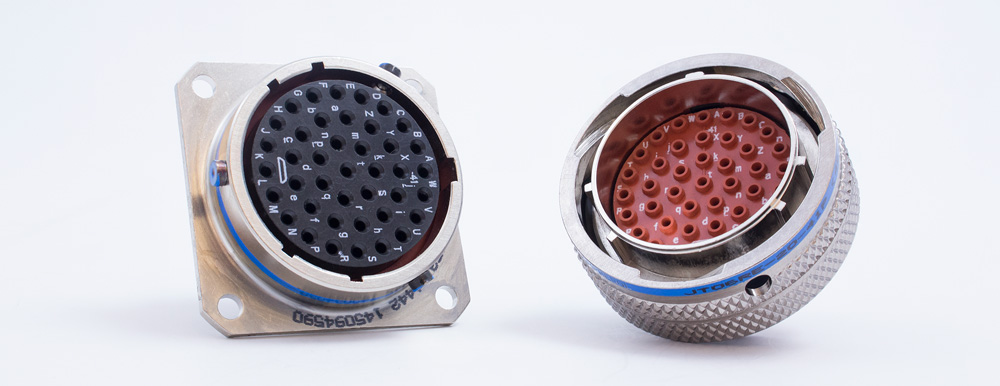

MIL-DTL-38999, otherwise known as D38999 or 38999, are high-density, circular connectors with threaded or bayonet coupling, available with crimp or solder contacts in various contact arrangements. D38999 connectors are designed for environmental resistance with an operational temperature range of −65 to +200 °C ( -85 to 392 °F) and are one of the most popular and widely used MIL-SPEC connectors on the market for both military and commercial aerospace applications due to their versatility and reliability.

There are several series of MIL-DTL-38999 connectors:

|

MIL-DTL-5015 |

MIL-DTL-5015 circular connectors feature threaded coupling and single-key/keyway polarization with a variety of shell sizes and insert arrangements to accommodate a range of wire and cable types. These connectors are widely used in applications that require dependable electrical connections in harsh environments. They’re popular as power connectors for high power and high voltage applications due to their robust construction and ability to handle high currents. |

MIL-DTL-26482 |

MIL-DTL-26482 connectors are miniature bayonet connectors with quick disconnect features. These connectors are used in applications that require quick, secure connections that are resistant to vibration and have excellent environmental sealing. |

MIL-DTL-83723 |

MIL-DTL-83723 circular connectors feature threaded coupling and offer configurations for general-purpose (Class G), high-temperature (Class H), and firewall applications (Class K). They are known for their durability, corrosion resistance, and ability to maintain secure connections under vibration and mechanical stress. They’re compatible with a wide range of wiring needs due to a range of shell styles, sizes, and contact arrangements. |

MIL-DTL-22992 |

MIL-DTL-22992 connectors are heavy-duty circular connectors with threaded coupling for power and signal applications. The Class L variant features robust construction, high current capacity between 40 and 200 amperes, and resistance to harsh environments that make it ideal for heavy-duty power distribution. |

MIL-SPEC Connector Derivatives

Amphenol doesn’t just offer connectors within standard MIL-SPEC boundaries; customization beyond MIL-SPEC standards to craft any interconnect solution to meet your unique needs is available through our 38999 Plus catalog.

Whether it’s signal connectors, power connectors, hybrid or high-speed connectors, 38999 Plus presents a massive inventory of MIL-SPEC styles and options to overcome any interconnect challenges.

Applications

- Military Aircraft

- Commercial Aircraft

- Naval Surface Ships

- Submarines

- Ground Vehicles

- Missile Systems

- Unmanned Vehicles

- Electric Military Vehicles

- Satellites

- Spacecraft

- Avionics Systems

- In-Flight Entertainment Systems

- Landing Systems

- Environmental Control Systems

- Fuel Management Systems

- Refueling Systems

- Power Distribution Systems

- Aircraft Braking Systems

- Communication Systems

- Cabin and Exterior Lighting

- Battery Management Systems