High Power and High Voltage Connectors and Contacts

| Product Line |

Description & Coupling Type |

Total Amperage Range (30°C heat rise) |

Connector Size Range |

Signal Contact Availability |

Contact Gauge Range |

Max Temp Rating (°C)* |

Service Rating (voltage rating) |

Shell Material |

Standard Contact Termina- tions |

Military Specification Reference |

Circular or Rectangular |

Common |

|

High Power Series |

Heavy Duty | 40 to 1200 |

Medium to Large |

Power and Signal |

0 to 16 | 150 to 200+ |

Same as 5015 | Aluminum or Stainless Steel |

Crimp, Solder, Bus bar, Threaded Post, PC Tail |

MIL-DTL-5015 | Circular | Hybrid and Conventional Ground Vehicles, Power Boxes |

|

MGT Bayonets |

Heavy Duty Quick Disconnect (1/4 turn bayonet) |

13 to 1000 |

Medium to Large |

Power and Signal |

0 to 16 | 125 to 200 |

Same as 5015 | Aluminum or Stainless Steel |

Crimp, Solder, Busbar |

MIL-DTL-5015 | Circular | Hybrid and Conventional Ground Vehicles, Power Boxes |

|

Tri-Power

|

High Current, medium duty, D38999-style interface |

240 to 620 |

Medium to Large |

Power Only | 0 to 8 | 150 | By arrangement |

Aluminum or Stainless Steel |

Crimp | MIL-DTL-38999 | Circular | Power Systems |

|

Matrix 5015 |

Medium Duty, threaded |

13 to 1000 |

Small to Large |

Power and Signal |

0 to 16 | 175 to 200 |

Same as MGT | Aluminum or Stainless Steel |

Crimp | MIL-DTL-5015 | Circular | High power in Aircraft/ Drones, ground support |

|

Ram-Lock with High |

Postive Locking PushPull | 70 to 500 | Small Medium | Power Only | 4/0 to 12 |

260 | Same as 5015 | Aluminum or Stainless Steel |

Crimp, Solder, Bus bar, Threaded Post, PC Tail |

None | Circular | eVTOL, battery terminals, vehicle charging |

|

38999 with High |

Medium Duty | 5 to 560 | Small to Medium |

Power and Signal |

4 to 22D |

200 | Per D38999 | Aluminum or Stainless Steel |

Crimp | MIL-DTL-D38999 | Circular | Avionics, directed energy weapons, eVTOL, power distribution |

|

BOB (Best of Both) |

Heavy Duty, Jack-Screw/ Rack and Panel |

up to 2000 |

Medium-Extra Large | Power and Signal |

0 to 16 | 200 | Same as 5015 | Aluminum or Stainless Steel |

Crimp, Solder, Bus bar, Threaded Post, PC Tail |

MIL-DTL-5015 | Rectan-gular | Military ground vehicle power distribution systems |

|

Series Five with High |

Medium Duty, Triple Start Thread Coupling |

5 to 500 | Micro-Miniature to Medium |

Power and Signal |

12 to 22D |

200 | Exceeds D38999 (Higher Voltage) |

Aluminum or Stainless Steel |

Crimp | MIL-DTL-D38999 | Circular | Aircraft, C4ISR, Commercial Space Avionics |

|

Matrix 38999 |

Heavy Duty, Triple Start Thread Coupling |

140 to 1000 |

Medium to Large |

Power and Signal |

0 to 16 | 200 | Same as 5015 | Aluminum or Stainless Steel |

Crimp, Solder, Bus bar, Threaded Post, PC Tail |

MIL-DTL-D38999 and MIL-DTL-5015 |

Circular | Shipboard, power distribution |

|

PowerSafe

|

Medium Duty, Triple Start Thread Coupling |

16 to 400 | Medium to Large (size 13, 17 and 25) |

Power only | 6 to 16 | 175 to 200 |

Up to 500 volts |

Aluminum, Stainless steel, marine bronze |

Crimp | VG96944- 04 - Derived from MIL-DTL-38999 series III |

Circular | Battlefield, Ground vehicle, C4ISR and harsh industrial markets |

|

MIL-DTL-22992 & |

Heavy Duty, Threaded |

40 to 200 | Large | Power and Ground |

1/0 to 6 | 175 | By arrangement |

Aluminum | Crimp | MIL-DTL-22992 | Circular | Battlefield power (Shelters, Generators) |

|

QWLD/QWL |

Heavy Duty, Threaded |

23 to 800 | Medium to Large |

Power and Signal |

0 to 16 | 175 | Same as 5015 | Aluminum | Crimp, Solder |

MIL-DTL-22992 | Circular | Ground support equipment, Industrial and commercial use |

|

D38999 |

Medium Duty, Triple Start Thread Coupling |

1 to 560 | Small to Medium |

Power, Signal, and High Speed |

8 to 22D |

175 to 200 |

Per D38999 | Aluminum, Composite, Stainless Steel |

Crimp | MIL-DTL-38999 | Circular | General Use Military/ Aerospace |

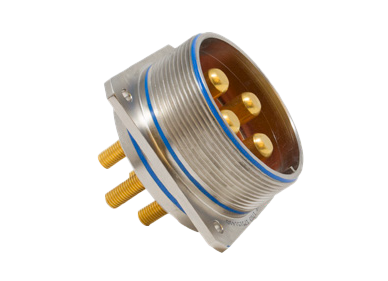

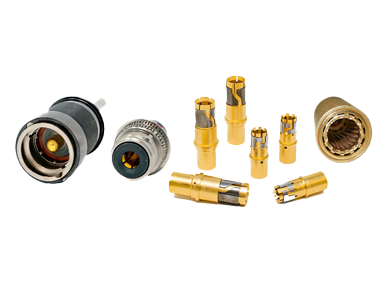

High Power Connectors

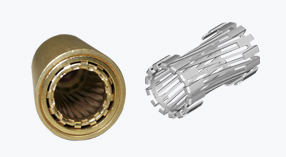

High Power Contacts

High Voltage Connectors

More Voltage and Power is the Answer

At Amphenol Aerospace, we have an extensive history of providing high-voltage and high-power solutions. Our legacy dates back to the Second World War when our Sidney plant produced the Scintilla Magnetos that powered advanced radial aircraft engines with high-voltage electrical energy.

Nowadays, we continue to focus on providing interconnect solutions, but with different products and applications, such as our High Power 38999 and High Voltage 38999 connectors, HVDC, custom busbars, and more. We remain dedicated to developing connectivity solutions for electric powertrains that propel evolving technologies like electric and hybrid-electric military vehicles and all-electric urban air mobility aircraft. The electrification of everything is underway, and power and voltage requirements are only going to continue to grow as this technology matures.

As electrified technology continues to scale at a rapid pace, it’s crucial that today’s interconnect solutions are up to the task. At Amphenol Aerospace, we’ve determined more voltage and power is required to support next-generation power requirements.

Imagining an Electrified World

The International Energy Agency (IEA) anticipates renewable energy to account for approximately 80 percent of global electricity demand in the coming decade. As renewable energy sources continue to grow and the world shifts toward electrification, military and aerospace technology is no exception. Governments, militaries, and corporations view this technology as a beneficial way to reverse the effects of climate change, as well as a force multiplier and a catalyst for strong economic growth. The market for electric aircraft and electric military vehicles is projected to grow substantially, with estimates reaching approximately $30 billion and $17 billion respectively by 2030, as new innovative technologies such as hybrid-electric tactical vehicles and electric vertical takeoff and landing (eVTOL) aircraft take to the roads and skies.

Meanwhile, consumer electric vehicles have begun to take off. Just about 17,000 EVs were on the road globally in 2010. By 2021, there were more than 16 million.

It's important that interconnect components keep up with the swift pace of electrified innovations. At Amphenol Aerospace, we believe that more voltage and power is critical to meeting the voltage and power requirements of this evolving technology. Our connectors can reliably and safely facilitate high currents and high voltages, and we're committed to delivering powerful and reliable interconnectivity solutions for electric applications as we move into the transformative decades ahead.

Electric Vertical Take-Off and Landing (eVTOL) Aircraft

eVTOL technology is slated to revolutionize urban air mobility. These nimble, all-electric aircraft are poised to remake transportation in urban areas while delivering lower emissions and faster arrival times. They are also power-hungry platforms. Our high-voltage and high-power connectors and contacts are uniquely positioned to meet these extensive power requirements.

Electric and Hybrid-Electric Military Vehicles

It’s not just consumer vehicles going electric; the military is pursuing electrification on a mass scale too. Several promising programs are in the works, such as the electric Joint Light Tactical Vehicle (eJLTV) and Optionally Manned Fighting Vehicle (OMFV), as militaries around the world begin to position themselves for an electric future. At Amphenol Aerospace, we embrace this future with a suite of products ready to meet next-generation military vehicle power standards.

Charging Systems

Just like internal combustion engines need to be refueled, electric powertrains need to be recharged. And as more vehicles and infrastructure become electrified, megawatt charging stations will play a crucial role in providing high-speed charging for the large-capacity batteries that power electric systems. Amphenol Aerospace's high voltage and high-power connectors can be relied on to facilitate the extensive power transfers and thousands of volts of direct current needed to operate the latest charging technologies.

5015%20Modular%20Connectors.png)